أصبحت معدات تصنيع الأقمشة غير المنسوجة Meltblown لا غنى عنها في الصناعات التي تتراوح من المواد الطبية وتنقية الهواء إلى تعزيز النسيج الأرضي والمواد الماصة الصناعية. للمشترين B2B, the decision to invest in meltblown production technology is no longer just about expanding capacity; it is about securing long-term competitiveness, enhancing product precision, and strengthening supply chain resilience.

This in-depth guide explores the fundamentals, essential machine configurations, production workflow, and critical factors that manufacturers must evaluate before entering or upgrading the meltblown nonwoven sector.

Understanding Meltblown Technology and Its Industrial Importance

Meltblown nonwoven production is a highly specialized process that uses high-velocity hot air to stretch and attenuate polymer melt into ultrafine fibers. These fibers form a web structure with exceptional filtration properties, making meltblown fabric irreplaceable in many performance-driven applications.

Why Meltblown Equipment Matters to B2B Buyers

• Control over fiber fineness ensures precise filtration grades

• Automation improves output stability and reduces labor dependency

• High uniformity supports advanced applications like N95 filter media

• On-site production reduces reliance on volatile global supply networks

Today’s buyers also rely on تخصيص الخط غير المنسوج to tailor machine widths, die designs, filtration characteristics, and production speed according to specific industry needs. The right configuration directly influences operational ROI, product performance, and downstream market success.

Explore more in this guide: تخصيص الخط غير المنسوج

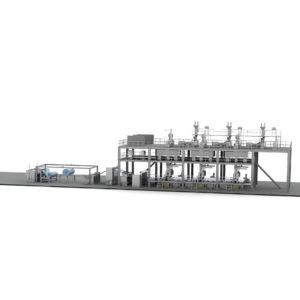

Core Components of Meltblown Nonwoven Fabric Making Equipment

A modern meltblown line is a sophisticated integration of mechanical precision, polymer engineering, and intelligent control systems. B2B buyers benefit from understanding the major components that determine output quality and energy efficiency.

1. Polymer Feeding and Extrusion Unit

The extruder melts and pressurizes raw PP or specialty polymers. Stable temperature control is crucial for achieving consistent fiber diameter.

2. Meltblown Die Assembly

Often considered the heart of the machine, the die determines fiber fineness and fabric uniformity. Parameters like hole density, die width, and air gap calibration significantly affect final product performance.

3. نظام الهواء الساخن

عالية السرعة, heated air streams stretch the polymer into ultrafine fibers. Buyers must evaluate air pressure consistency, energy consumption, and thermal stability.

4. Collector System

The fiber web is deposited onto a moving screen. The precision of suction and web-laying mechanisms determines fabric uniformity and tensile strength.

5. Winder and Final Processing

Automation reduces downtime and maintains a continuous production rhythm.

For industrial applications such as geotextiles, meltblown equipment is also often integrated with a full آلة غير منسوجة للنسيج الجيوتكستيل, creating a multi-layered production ecosystem that supports drainage layers, reinforcement layers, and soil stabilization solutions. Learn more here: آلة غير منسوجة للنسيج الجيوتكستيل

Key Applications That Drive Market Demand for Meltblown Nonwovens

Medical Filtration and PPE

Meltblown nonwoven fabric remains the gold standard for respirator filtration layers, surgical mask cores, and medical-grade air purification.

ترشيح الهواء والسوائل

Precision fiber control makes meltblown fabric ideal for HVAC filters, oil-water separation systems, and high-capacity dust collectors.

Industrial Sorbents

Ultrafine fiber structures increase adsorption efficiency, making meltblown pads essential for oil spill cleanup and industrial maintenance.

Geotextile and Construction Applications

Although spunbond dominates heavy-duty geotextiles, meltblown layers enhance filtration and drainage performance in composite geotextiles.

Battery Separator Materials

Emerging EV markets increasingly use meltblown separators in lithium-ion cell production, creating new demand trajectories for manufacturers.

What B2B Buyers Must Evaluate Before Investing

Investing in meltblown equipment is a high-stakes decision. B2B manufacturers should carefully assess the following:

1. Product Positioning and Required Filtration Grades

Consider whether you need N95/N99 filtration, industrial-grade sorbents, or nonwoven layers for composite fabrics. Each requires different machine configurations.

2. Output Capacity and Line Width

A typical meltblown line ranges from 600mm to 3200mm widths. Larger widths support mass production, but require greater investment in automation and temperature management.

3. Raw Material Compatibility

Polypropylene is standard, but markets for TPU, جيش التحرير الشعبى الصينى, and high-performance polymers are growing. Ensure your equipment supports them if targeting emerging applications.

4. Maintenance and Operational Costs

Evaluate die cleaning mechanisms, filter replacement cycles, وتوافر قطع الغيار.

5. Level of Automation

Modern buyers seek:

• PLC-driven monitoring

• Automatic winder control

• Precision die temperature balancing

• Energy-efficient air systems

The right automation level directly influences competitive advantage.

How Meltblown Equipment Drives Profitability and Market Expansion

A well-designed meltblown line helps manufacturers:

• Reduce outsourcing costs

• Capture high-margin filtration markets

• Strengthen supply chain control

• Expand product portfolios

• Improve delivery flexibility for international buyers

في أثناء, modular line architecture supports phased expansion, allowing businesses to scale without significant factory restructuring.

Manufacturers supplying filtration, صحة, السيارات, التكسية الأرضية, and energy markets will find meltblown equipment a strategic long-term asset for boosting operational resilience and innovation.

حول قوان لونغ

Guanlong is a leading manufacturer of nonwoven machinery, specializing in meltblown, سبونبوند, رسالة قصيرة, and fully customized nonwoven production lines. With deep engineering expertise, advanced manufacturing capabilities, and a commitment to high-performance industrial solutions, Guanlong supports global manufacturers in filtration, التكسية الأرضية, صحة, and industrial materials markets. From precision meltblown systems to turnkey nonwoven line customization, Guanlong delivers reliable technology that helps B2B clients increase efficiency, expand market presence, and achieve consistent product quality.