لماذا تعد الآلات غير المنسوجة أمرًا حيويًا لإنتاج الأقنعة الطبية

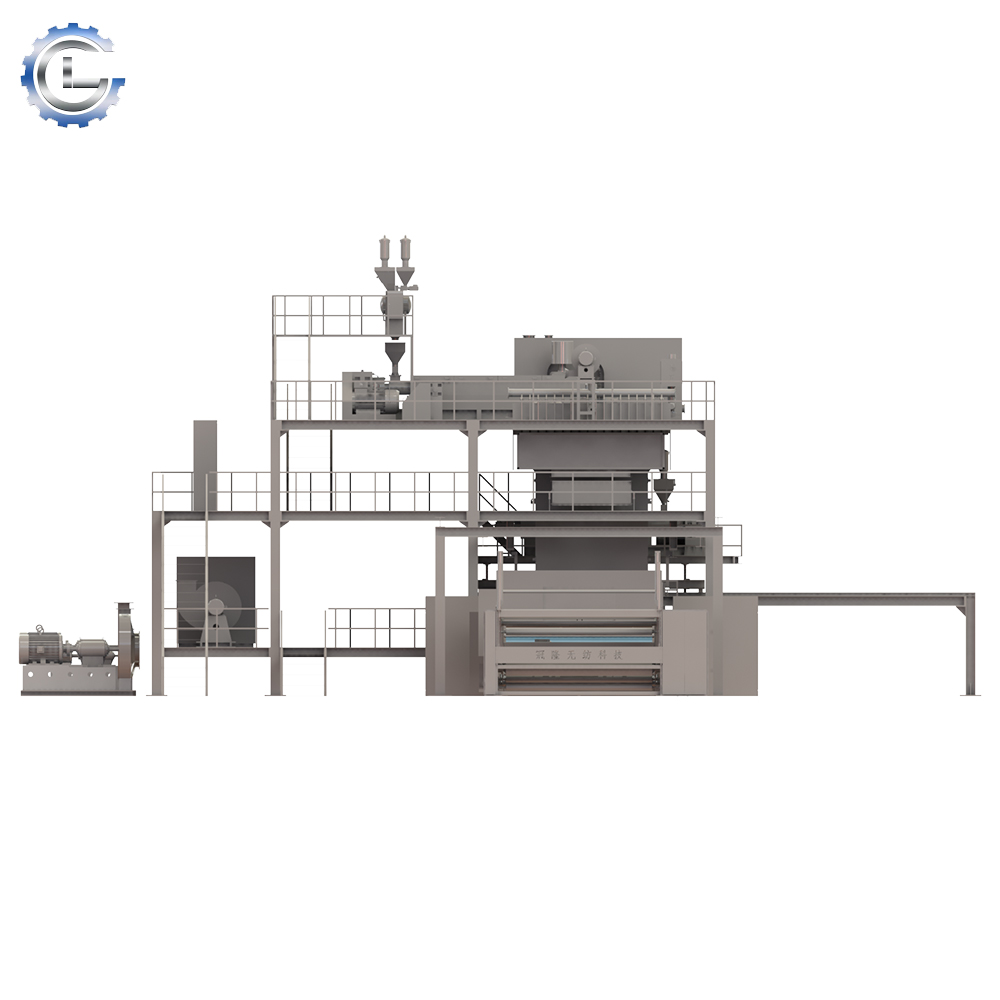

في الصناعة الطبية, تشكل المواد غير المنسوجة العمود الفقري للأقنعة الواقية. آلات غير منسوجة للأقنعة الطبية تمكن الشركات المصنعة من إنتاج منتجات عالية الجودة, ثابت, والأقمشة الآمنة اللازمة للأقنعة الجراحية, أجهزة التنفس N95, وغيرها من معدات الوقاية الشخصية الطبية.

مع تزايد الطلب على الأقنعة الطبية في جميع أنحاء العالم, كفاءة, مصداقية, والدقة في الإنتاج أمر بالغ الأهمية. تضمن الآلات غير المنسوجة الحديثة توزيعًا موحدًا للألياف, كفاءة الترشيح الأمثل, ومعدلات إنتاج مستقرة, والتي تمثل اهتمامات رئيسية للمشترين B2B في قطاعي الرعاية الصحية والتصنيع.

الميزات الرئيسية للآلات غير المنسوجة لتصنيع الأقنعة

يبحث المشترون الصناعيون عن الآلات التي تجمع بين الأداء, متانة, والفعالية من حيث التكلفة. وتشمل الميزات الرئيسية:

- سرعة إنتاج عالية: القدرة على إنتاج كميات كبيرة من الأقمشة غير المنسوجة دون المساس بالجودة.

- التحكم الدقيق في الألياف: يضمن سماكة وكثافة متسقة, حاسمة لأداء الترشيح.

- التشغيل الآلي: يقلل من تكاليف العمالة, يحسن السلامة, ويزيد من الإنتاجية.

- عروض وأنواع الأقمشة المرنة: يدعم أحجام القناع المختلفة والمواصفات غير المنسوجة.

الاستثمار في الجودة العالية آلة النسيج غير المنسوج يسمح للمصنعين بتلبية متطلبات السوق مع الحفاظ على معايير المنتج والكفاءة التشغيلية.

اختيار الآلات غير المنسوجة المناسبة

يعتمد اختيار الآلات المناسبة على القدرة الإنتاجية, نوع المادة, ومعايير الجودة:

- القدرة الإنتاجية: تقييم احتياجات الإنتاج اليومية لتحديد حجم الماكينة وسرعتها المناسبة.

- توافق المواد: تأكد من قدرة الماكينة على التعامل مع PP spunbond, Meltblown, أو المواد المركبة.

- كفاءة الطاقة: تعمل الآلات الحديثة على تقليل تكاليف التشغيل مع الحفاظ على الإنتاج العالي.

- الخدمة والدعم: تعد خدمة ما بعد البيع ودعم الصيانة الموثوقة أمرًا ضروريًا للإنتاج المستمر.

أفضل ممارسات الصيانة والتشغيل

لا يعتمد الإنتاج الفعال على الماكينة نفسها فحسب، بل يعتمد أيضًا على التشغيل والصيانة المناسبة:

- التنظيف والتفتيش المنتظم: منع تراكم الألياف, تلوث, والتآكل الميكانيكي.

- استبدال المكونات الهامة في الوقت المناسب: الفوهات, بكرات, ويجب فحص عناصر التسخين واستبدالها حسب الحاجة.

- تدريب المشغلين: يقلل الفنيون المهرة من وقت التوقف عن العمل ويضمنون جودة النسيج المتسقة.

- مراقبة معلمات الإنتاج: مراقبة درجة الحرارة في الوقت الحقيقي, سرعة, ويساعد توزيع الألياف في الحفاظ على معايير عالية.

يؤدي تنفيذ أفضل الممارسات هذه إلى إطالة عمر الماكينات وزيادة عائد الاستثمار إلى الحد الأقصى.

حول Guanlong - المورد الموثوق به للآلات غير المنسوجة

شركة Guanlong متخصصة في تصميم وتصنيع الآلات غير المنسوجة المتقدمة للأقنعة الطبية والتطبيقات الصناعية الأخرى. تم تصميم أجهزتنا لتحقيق كفاءة عالية, متانة, والدقة, مساعدة الشركات المصنعة على تلبية الطلب العالمي المتزايد.

عروضنا تشمل:

- آلة أقمشة غير منسوجة عالية الأداء لأقمشة PP Spunbond والأقمشة المركبة

- دعم الخبراء من الرائدة مصنعي الآلات غير المنسوجة

- حلول مخصصة لتلبية متطلبات الإنتاج المحددة

- الخدمة الفنية طويلة الأجل ودعم قطع الغيار

الشراكة مع Guanlong تضمن الموثوقية, فعال, والإنتاج الآمن للمواد غير المنسوجة الطبية.