وصف المنتج

1.Company Profile:

2.تفاصيل المنتج

2-1:Main Technology data

1.Fabric width:1600mm(Availed width)

2.الحد الأقصى لقطر اللف:Φ1500MM

3.سعة:According70 g/㎡,9-10t/24h

4.Monofilament size:<2.5d

5.Fabric weight:10~200 g/㎡

6.Designed speed:150M/MIN ;(Working speed:130 M/MIN)

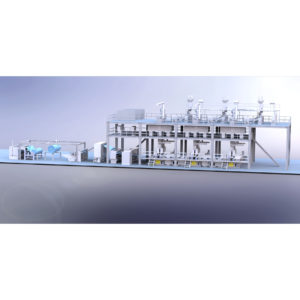

7.حجم المعدات:length 15 *width10* height 11

The following word will introduce the features of S Spunbond Nonwoven Machine:

1. S Spunbond Nonwoven Machine adopts an intelligent electrical control cabinet and spinning drafting system. يتميز وضع التحكم في النظام بالسرعة المتقدمة المعدلة بتردد التيار المتردد, الاتصالات الرقمية المتزامنة بالكامل.

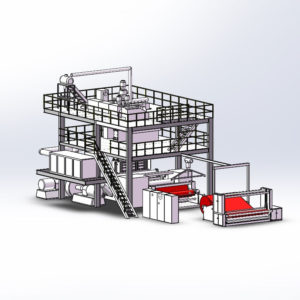

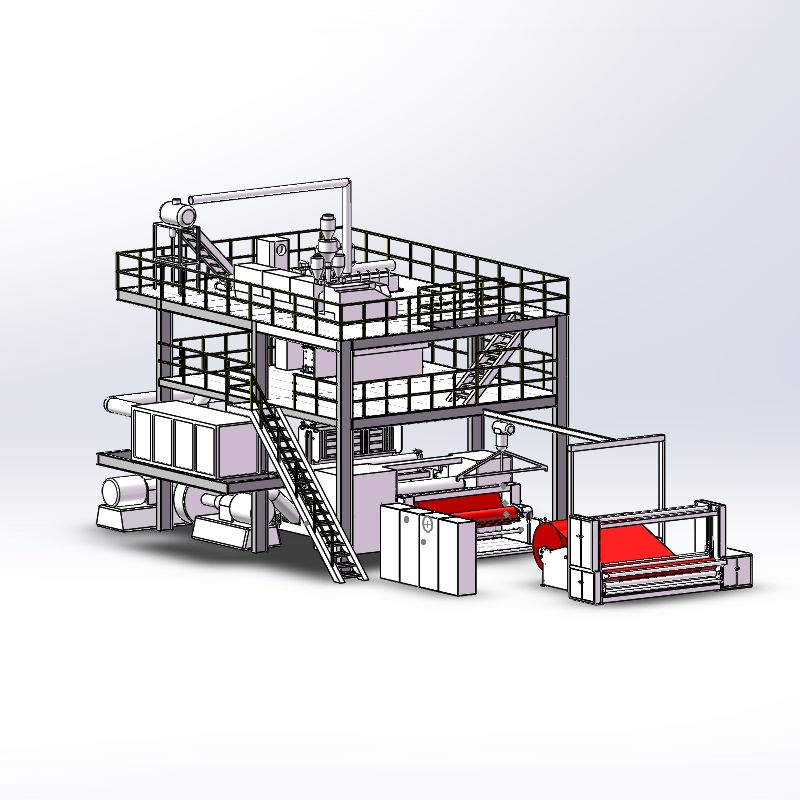

2. S Spunbond Nonwoven Machine is featured by lower investment, compact construction, small covering area, and labor-saving.

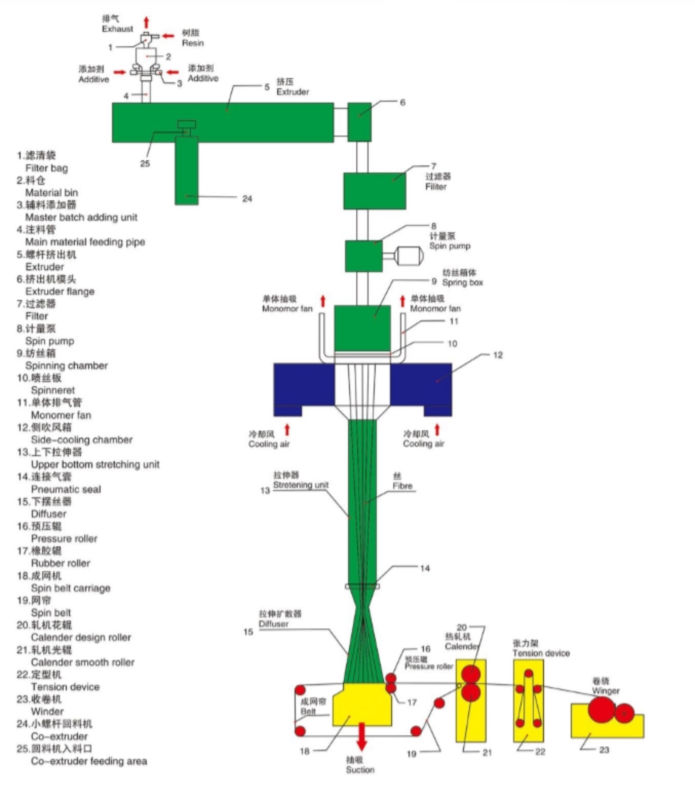

3. S Spunbond Nonwoven Machine is a single-beam professional manufacturer of single-layer nonwoven fabric equipment which is manufactured for PP/PET/PLA/Bi-Component Spunbond nonwoven fabrics’ إنتاج. بعد إدخال المواد الخام, الخضوع لعملية البثق, الدوران, التبريد, إغلاق تمدد الهواء, تشكيل الويب, التقويم, اللف والقطع حسب المتطلبات ثم تعبئتها للتخزين والتسليم.

4. As the fabrics have great intensity, قدرة جيدة على التنفس, and good feeling, they are widely used for various fields such as home decoration, furniture covers, clothing shoe leather, أغطية الحماية الصناعية والزراعية, medical and sanitary supplies, beauty products and so on.

2-3 المقياس التقني

3.الأجزاء الرئيسية

1.Maximum working pressure: 16MPa

2.Maximum working temperature: 310℃

3.Single cylinder filter area: 0.5-19㎡

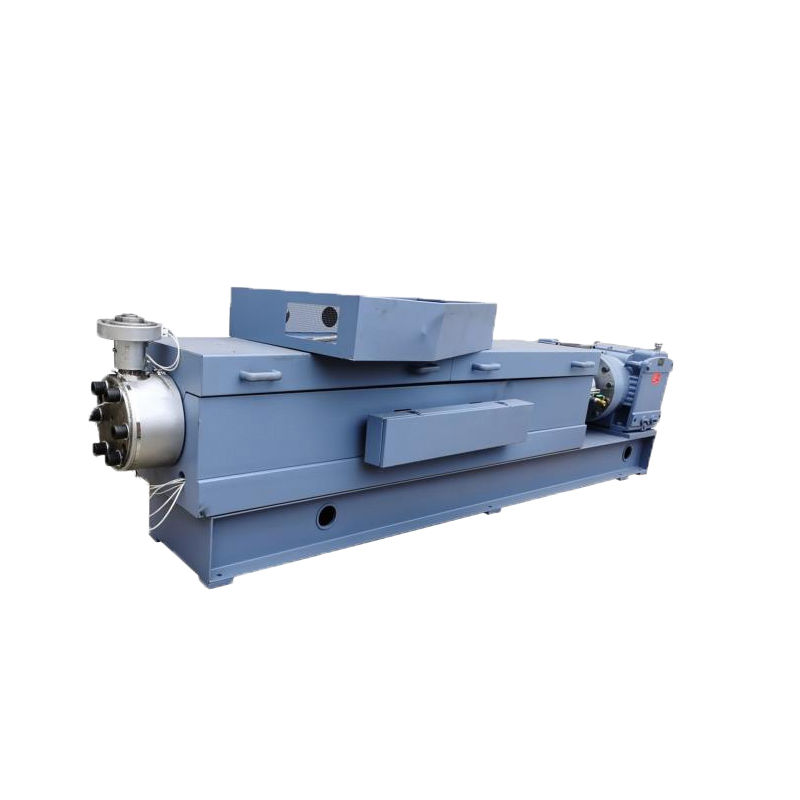

1. Aspect ratio L/D=30:1.

2.قطر المسمار: Φ150mm

3.Siemens Bede AC motor 110kw, Fuji frequency controller

4.The spiral cylinder and screw are made of high-strength nitriding steel, equipped with resistance heater, divided into several heating zones, including a full set of electrical control devices, including power, temperature control, pressure control, إلخ. see the plasticizing capacity of electric control part for details

1.إن أسطوانة القيادة الرئيسية مصنوعة من أنبوب فولاذي غير ملحوم

2.سرعة القطع:800-1000م/دقيقة

3. محرك سيمنز بيدي AC, 15كيلووات * 1 تعيين, فوجي تحكم التردد المتغير من اليابان

4.الحد الأدنى لعرض القطع: 100 مم

5.الحد الأقصى لقطر اللف: 1000مم

6.عدد سكاكين القطع 16 مجموعات

7. 3 مهاوي توسيع الغاز من ألياف الكربون

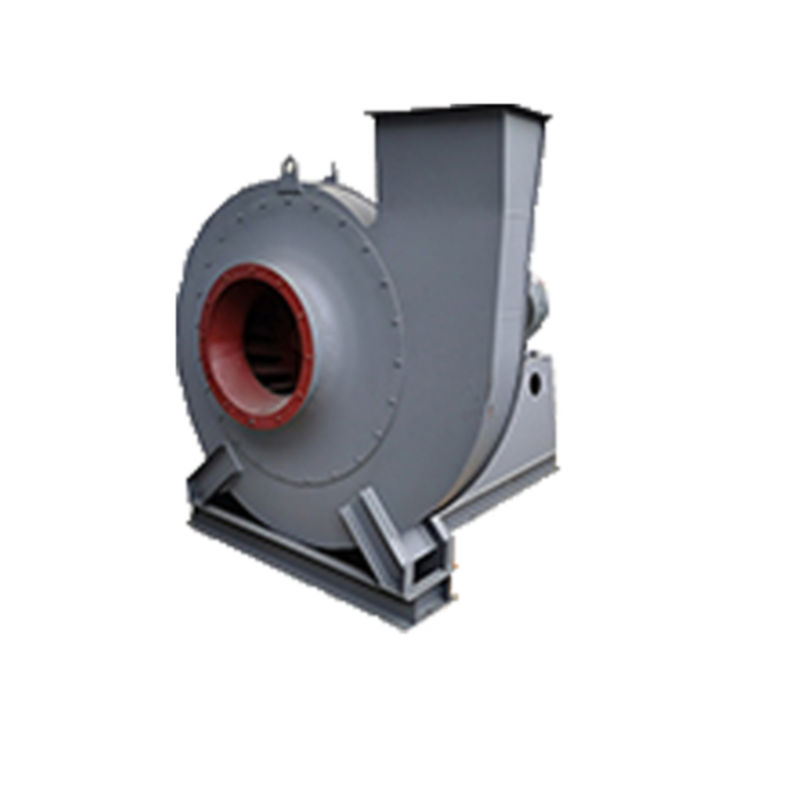

1.سرعة مروحة العادم قابلة للتعديل2.الملحقات: خلاط ثابت GD-SM-SO2

3.إجمالي حجم الهواء: 15000-23000 م³/ساعة

4.منظم ضغط الهواء: عاكس فوجي (RKC-F900)

5.قوة المروحة 75 كيلو وات * 1 تعيين, 90كيلوواط * 1 تعيين, بما في ذلك أنبوب العادم,ويتم تفريغ هواء الشفط إلى الخارج

6. قوة مروحة الهواء البارد 75 كيلو وات, 2مجموعات, تم اعتماد محرك Siemens Bede

1.قوة:45KW AC Motor

2.Heating: Oil Heating

1.Each spinning box can distribute the melt symmetrically and equivalently

2. The melt pipeline adopts compound casing and electric heating

3. The heating power of the heat-conducting oil furnace is 48KW; the maximum heating temperature is 300 degrees, and it is heated outside the oil furnace.

4.طلب

NONWOVENS APPLICATIONS

Guanlong Nonwoven lines are designed and manufactured in accordance with individual customer requirements. Their possible area of application is correspondingly wide.

Such as :

باكاج – كيس التسوق, تعبئة الأرز, تغليف الملابس, إلخ.

صحة – حفاضات الأطفال والكبار, النظافة الأنثوية, إلخ.

طبي – أقنعة الجراح, ملابس يمكن التخلص منها, إلخ.

أثاث – غطاء سرير, تغطية المقاعد, إلخ.

اِصطِلاحِيّ – المنسوجات الأرضية, زراعة, إلخ.

الترشيح – هواء, غاز, السوائل, إلخ.

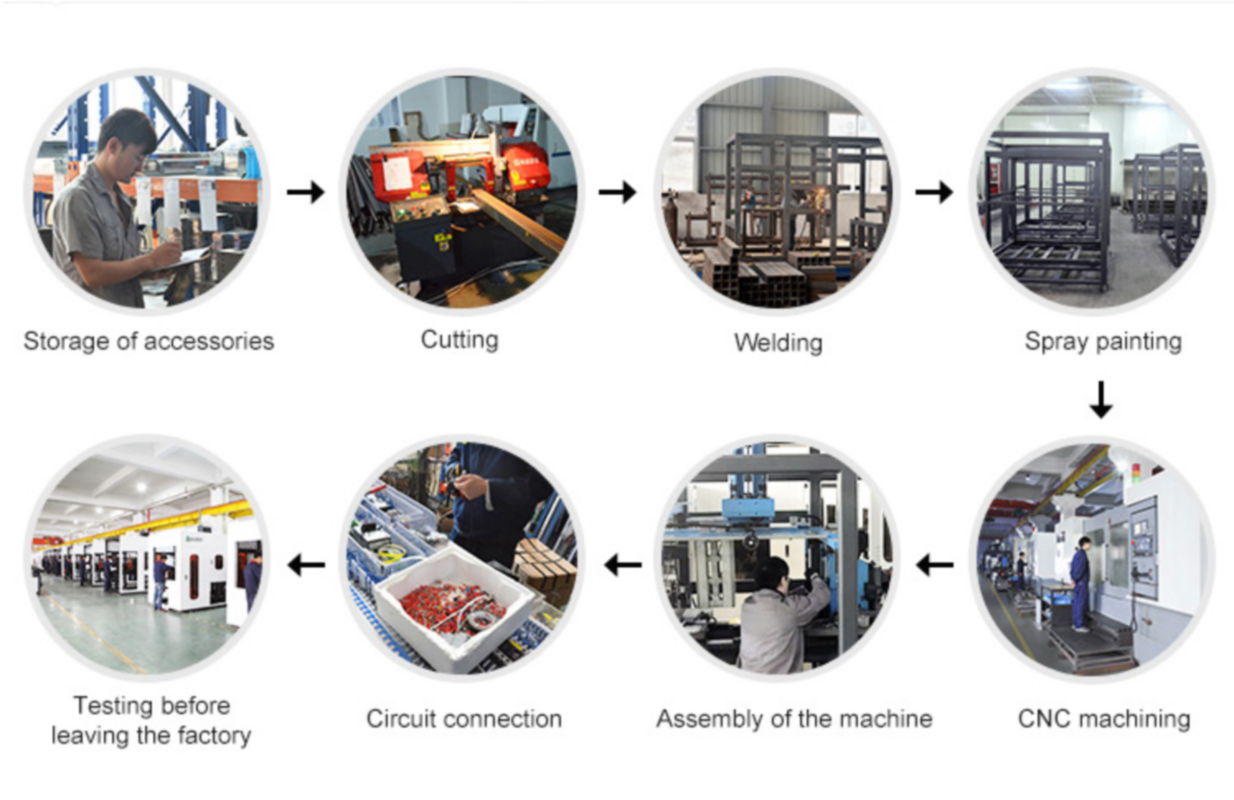

5.production process

6.خدمتنا

1.12 Hours—-We will give you reply within 12 hours.

2.Pre-sale service—-We provide your professional service in fluent English.

3.Delivery—-1~3 months.

4.Free Design—-Professional engineers, free designs.

5.الشهادات—-The third-party verification service provider.

6.After sales service—-OEM service provide; Design service provide; Buyer label provided.

7.التعبئة & شحن

Standard export packaging:

1. Apply anti-rust oil to the equipmenteasy rustypart and carry out anti-rust treatment.

2. The whole machine was wrapped with stretch film for protection,and the equipment control cabinet and other components are protected against shock with packaging materials like XPS foam board and EPE foam sheet.

3. Reinforceeasy-movepart of the equipment.

4. Put desiccant before packaging to avoid rusting equipment during sea transportation.

8.التعليمات

Q1:What’s your warranty policy?

A1:The Seller will guarantee the machine for 18 months since the date of shipment(that is leaving from Seller’s factory) or the seller will guarantee the machine for 12 months since the date of starting installation and adjustment, whichever comes first.

Q2:What’s your minimum order quantity?

A2:Min order quantity:1 set or by negotiate with each other.

Q3:What package do you use for the product?

A3: Be Coated with anti-corrosion oil, and covered with plastic film, then packed in wooden box.

Q4:Do you have technical instruction if I buy your product?

A4:Please read the user manual carefully for your reference, we have detail instruction on it. If your problems still can not be solved, welcome to contact us for help.

Q5:What is your overseas service?

A5:We will provide high quality overseas service ,our technical staff will be able to provide you with technical support, for you personally to overseas assembly and test equipment.

Q6:Will you conduct training for our staff here?

A6:Yes, we will provide technology support to factory technology, training for the relative person.

Q7:What are your terms of payment?

A7:We accept T/T, L/C.