Descripción del Producto

1.Perfil de la empresa:

Guanlong se ha centrado en la máquina de fabricación de telas no tejida 15 años. Combinamos tecnología avanzada internacional y proporcionamos varias soluciones holísticas de líneas de producción para los clientes de acuerdo con su solicitud..

Hasta ahora,Hemos fabricado cientos de líneas de producción automáticas completas para clientes de la India, Indonesia, Filipinas, Nepal, Rusia y otros países.

2.Detalles del producto

2-1.Datos principales

1.1. tipo de producto

SMS Spunbond Meltblown compuesto no tejido,Tela no tejida SS Spunbond Tela no tejida soplada en fusión

Tela no tejida soplada en fusión M

1.2. Ancho del producto:3200mm(Ancho estándar después del recorte)

1.3. Número de cabezas de matriz: 2 conjuntos de Spunbond, 2 conjunto de derretidos

1.4. Finura de fibra: sistema spunbond ≤1.6-2.0den, Sistema de derretimiento de derretimiento: 2~5μm

1.5.Rango de peso de tela:10-150g/ m2

1.6. Velocidad de producción máxima: 600m/min

1.7. Producción anual: 4500 toneladas/año

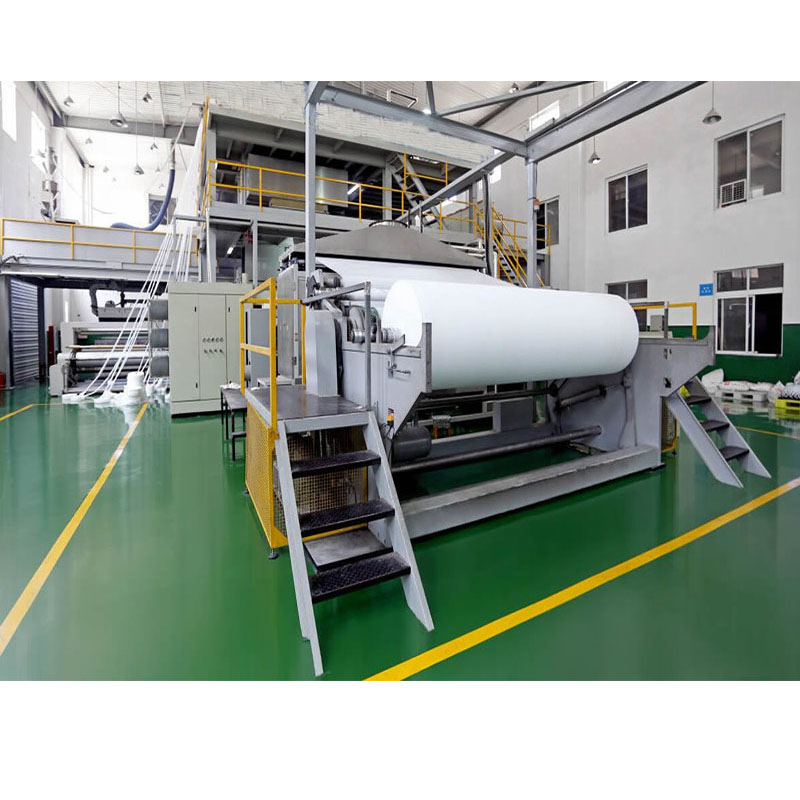

2. Descripción del Producto

La máquina para no tejidos SMMS Spunmelt es una línea compuesta para la producción de no tejidos que combina la técnica de fabricación spunbond y meltblown.. Tiene cuatro vigas en producción y se puede personalizar según sus demandas de producción..

Adopta un gabinete de control eléctrico inteligente y un sistema de dibujo giratorio.. El modo de control del sistema presenta una velocidad avanzada de frecuencia modulada de CA., comunicaciones sincronizadas totalmente digitales.

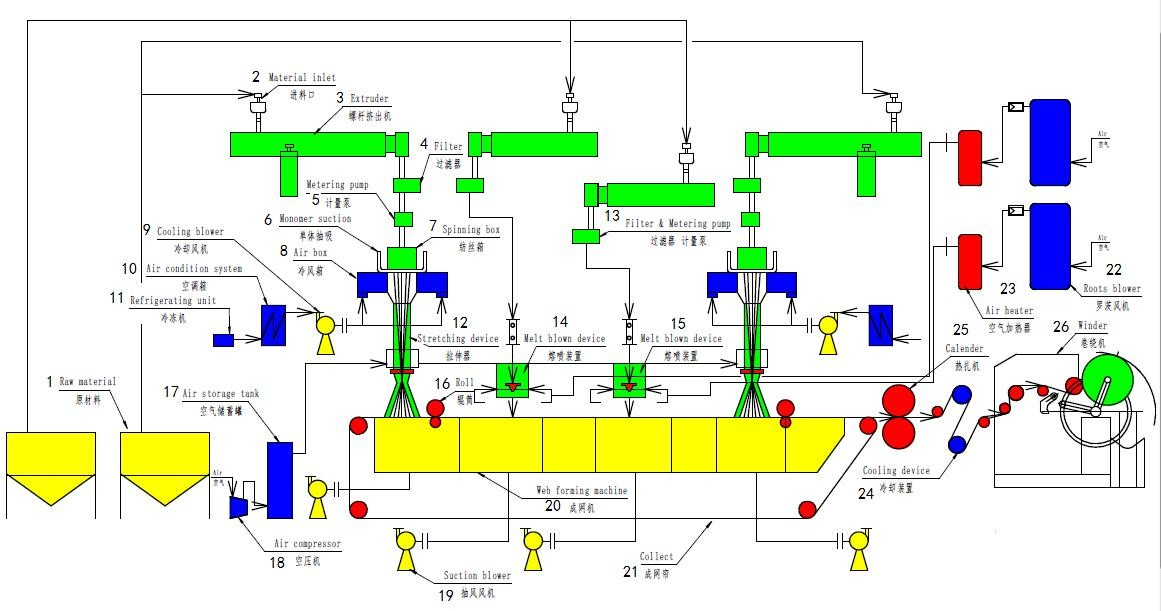

2-3.flujo de producción

La máquina no tejida SMMS Spunmelt se fabrica para telas no tejidas compuestas de PP. Después de la entrada de materias primas., Pasar por extrusión y fusión., filtración, medida, hilado, enfriamiento, extensión, difusión web, Unión térmica y corte según los requisitos y luego empaquetado para almacenamiento y entrega..

2-4.la especificación de la máquina smms

3.Partes principales

3-1 Extrusor de tornillo

1. Relación de aspecto L/D = 30:1.

2.Diámetro del tornillo: Φ150 mm

3.Siemens Bede AC Motor 110kW, Controlador de frecuencia de Fuji

4.El cilindro espiral y el tornillo están hechos de acero nitrurro de alta resistencia, equipado con calentador de resistencia, dividido en varias zonas de calentamiento, incluyendo un conjunto completo de dispositivos de control eléctrico, incluyendo poder, control de temperatura, control de presión, etc.. Consulte la capacidad de plastificación de la parte de control eléctrico para más detalles

3-2 Caja de hilatura con sistema de calefacción.

1)Cada caja de hilatura puede distribuir la masa fundida de forma simétrica y equivalente

2)La tubería de fusión adopta una carcasa compuesta y calefacción eléctrica.

3)La potencia de calentamiento del horno de aceite termoconductor es de 48 KW.; la temperatura máxima de calentamiento es 300 grados, y se calienta fuera del horno de aceite..

3-3 Hilera y componentes de hilatura.

1)Está hecho de acero de precisión resistente a altas temperaturas., 2800 * 256 de longitud, La apertura es 45S. /4 pares, y la hilera contiene aproximadamente 15600 agujeros (Los parámetros específicos están sujetos al fabricante.).

2)Cada conjunto de componentes incluye: Arandela de aluminio, placa de distribución, Pantalla de filtro de acero inoxidable multicapa revestida de aluminio

3-4 Soplado de aire de refrigeración (arriba y abajo) dispositivo de dibujo

1)El sistema de dibujo superior adopta una forma completamente cerrada., y está equipado con un dispositivo de hilera de elevación hidráulica.

2)La capa interior de vidrio templado plano., 12mm de espesor, adopta tecnología de hendidura

3)Se divide en canal de tiro., canal de difusión, dispositivo móvil. El sistema de tensión inferior está conectado con el sistema de tensión superior.. Está fabricado en acero inoxidable de alta calidad y tiene un mecanismo de ajuste.

4)Cantidad total de aire de succión: 25000m³/ h, temperatura del aire 20-30 ℃

5)La superficie exterior de los dispositivos de dibujo superior e inferior está provista de una capa aislante.

4.Nuestra ventaja

1. We have professional sales and engineers, are ready to send emergency repair parts in 24 horas, easily damaged parts in 5 days with professional knowledge.

2. We focus on customer service, all year non-stop service, personal training and so on.

3. Not only provide customer service, but also pre-sales system,

including solution to product selection, storage of parts, technical guidance, operating training, exchange management platform and so on.

4. Realizing the idea of focusing on customer success, creating value to customer.

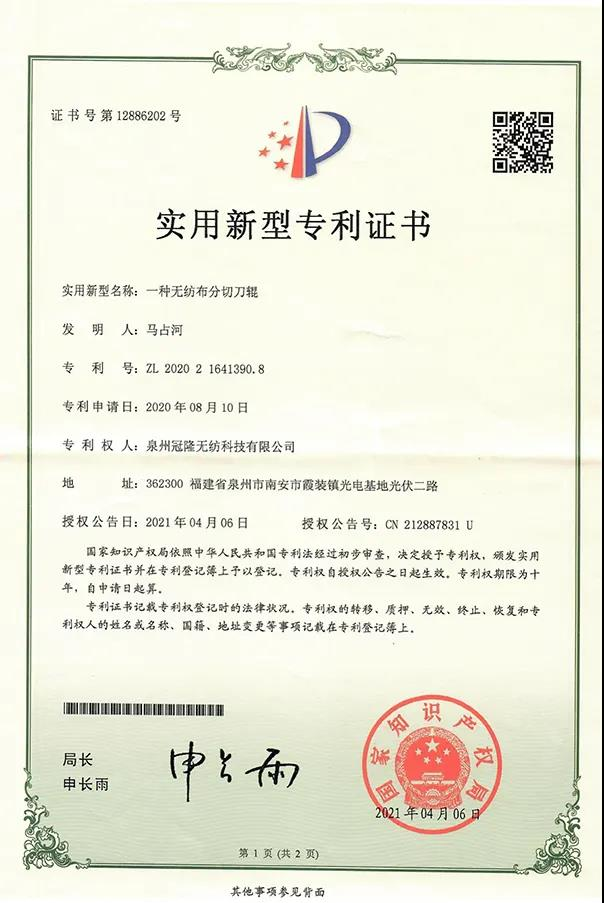

5.Certificado

5.Paquete y entrega

6.Preguntas frecuentes

Q1:¿Qué pasa con el plazo de servicio posventa? ?

A1:Debido a la pandemia de COVID-19, No podemos organizar que mi ingeniero venga a ayudarlo a instalar la máquina ahora mismo.,Brindamos servicio en línea.. Una vez terminada la pandemia de covid-19. Podemos organizar que mi ingeniero venga a ayudarlo con la instalación y capacitación de sus trabajadores.. Necesitas tomar toda la tarifa., Incluye costo de solicitud de VISA de ingeniero., cargo por boletos aéreos de ida y vuelta,cargo de alojamiento a tu lado, and salary 200USD/ day.

Q2:¿Qué tipo de servicio postventa me pueden brindar? ?

A2:Gracias a que logramos instalar más de 50 Conjunto de máquinas de tela no tejida en todo el mundo., Por eso tenemos una rica experiencia en instalación y capacitación de máquinas.. Nuestro equipo de servicio posventa ayudará a su gente a construir la máquina., e instalar la máquina paso a paso. Le proporcionaremos planos de instalación completamente de la máquina..

Q3:¿Cuál es la garantía y plazo de garantía de su empresa??

A3:12 meses después de terminar la instalación de la máquina