Descripción del Producto

1.Detalles del producto

1-1:Datos de tecnología principal

1.Ancho de tela:1600mm (Avistado ancho)

2.Diámetro máximo de devanado:Φ2000MM

3.Capacidad:Según 70 g/㎡,20T/24H

4.Tamaño de monofilamento:<2.5d

5.Peso de la tela:10~150g/㎡

6.Velocidad diseñada:350M/mi ;(Velocidad de trabajo:300 M/min)

7.Estándar de calidad del producto: Según las muestras confirmadas por ambas partes., según los datos confirmados por ambas partes.

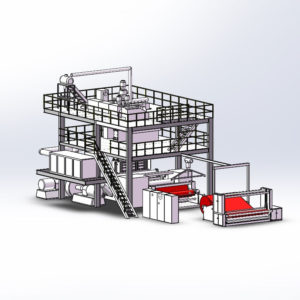

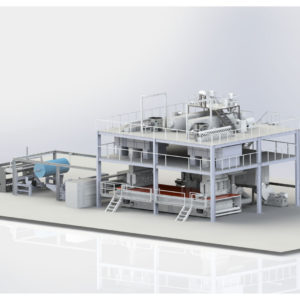

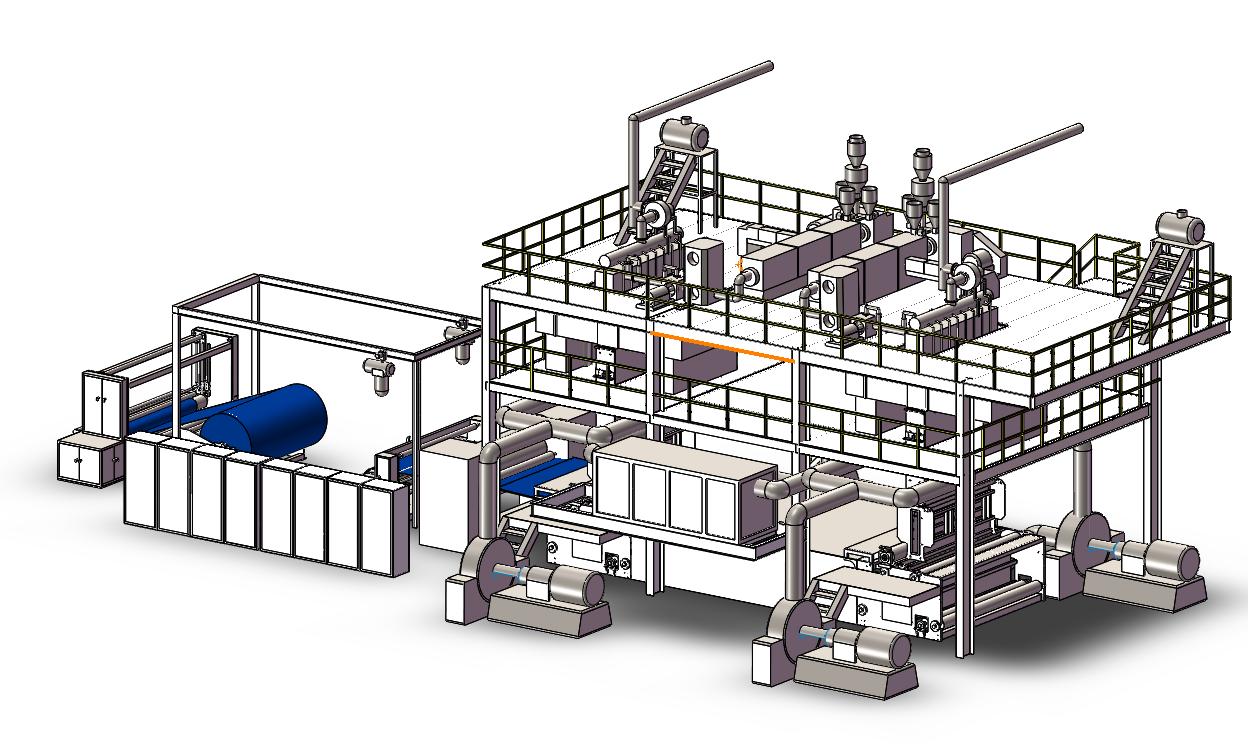

1. La máquina para tela no tejida SS adopta un gabinete de control eléctrico inteligente y un sistema de dibujo giratorio.. El modo de control del sistema presenta una velocidad avanzada de frecuencia modulada de CA., comunicaciones sincronizadas totalmente digitales.

2. La máquina no tejida SS es de doble haz, Posee una calidad claramente superior y una cantidad de producción claramente mayor que la máquina no tejida S..

Y la máquina no tejida SS funciona con alta eficiencia y bajo consumo de energía.. Basado en las características anteriores, La máquina no tejida SS puede ayudar a los clientes a ahorrar mano de obra y tener una amplia compatibilidad con diferentes requisitos elevados de producción..

3. SS Nonwoven Machine es el fabricante profesional de telas no tejidas de doble capa..

4. Sobre el paquete: Embalamos las piezas principales de la máquina en cajas de madera.; Las piezas eléctricas se embalarán con plástico y luego se embalarán en cajas de madera.; Con la estructura de acero, se empacarán en contenedores.

1-3 Parámetro técnico

2.Partes principales

1.Fuerza:7.5KW

2.Eje de expansión del aire:3200X3 PCS

3.Diámetro máximo del rollo de tela:1500milímetros

4.Máximo. peso de rollo:750Kg

Fuerza:4kilovatios

Velocidad:250 Metros/min

1.El principal rodillo de conducción está hecho de tubo de acero sin costura

2.Velocidad de corte:800-1000m/min

3. Siemens rezó AC motor, 15KW * 1 colocar, Controlador de frecuencia variable de Fuji de Japón

4.Ancho de corte mínimo: 100 milímetros

5.Diámetro máximo de devanado: 1000milímetros

6.Número de cuchillos para cortar 16 sets

7. 3 Pañales de expansión de gas de fibra de carbono

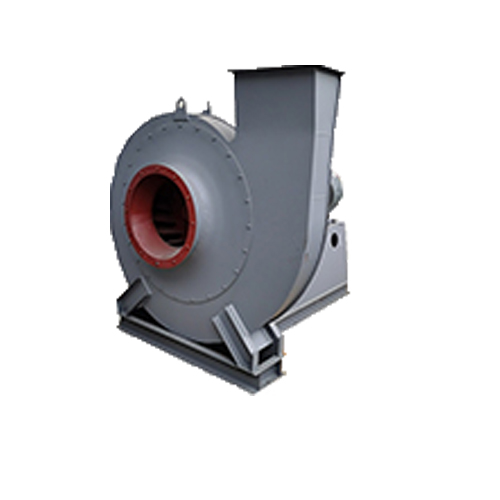

1.La velocidad del ventilador de escape es ajustable2.accesorios: GD-SM-SO2 MECHA ESTÁTICO

3.Volumen de aire total: 15000-23000 m³/ h

4.Regulador de presión del aire: Fuji Inverter (RKC-F900)

5.La potencia del ventilador es de 75kw * 1 colocar, 90KW * 1 colocar, incluyendo el tubo de escape,y el aire de succión se descarga al aire libre

6. El poder del ventilador de aire frío es de 75kw, 2sets, Se adopte el motor Siemens Bede

1. Sistema de circulación de agua fría, tuberías de agua de enfriamiento y torre de agua

2. El jefe del criocompresor se hace en Hanzhong, Taiwán,Porcelana,150T/H;

3.El sistema de suministro de agua está hecho de fibra de vidrio, y el consumo diario de agua diseñado se trata de 1 metro cúbico (Principalmente para el suplemento de agua de enfriamiento)

1.El spinneret calcinado a alta temperatura se usa para derretir una gran cantidad de polímero en las piezas y luego fluir hacia el contenedor de recolección en la parte inferior del horno

2. Integración automática, con baja alarma de vacío, Alarma de temperatura excesiva, alarma de corte de agua y otros dispositivos avanzados de protección de seguridad

3.Solicitud

4.Perfil de la empresa:

Guanlong es uno de los principales fabricantes de una línea no tejida completa en China. Nos centramos en la fabricación,venta e investigación & Desarrollo de líneas no tejidas. Comenzamos a trabajar en la fabricación de líneas no tejidas en el año. 2005.

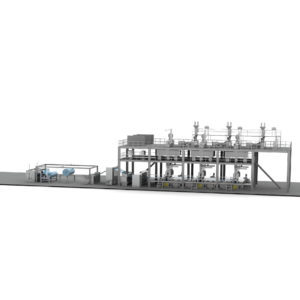

Principalmente fabricamos líneas no tejidas Spunbond, como un solo haz(Línea S), vigas dobles(Línea de ss) y tres vigas(Línea SSS), girar (Hilado & derretido) líneas no tejidas como S,SS,SSS,SMS,SSMS,SMS. Ssmxs,El ancho principal es de 1600 mm/2400 mm/3200mm. La gama de gramantos será de 10 gsm a 80 gsm con alto rendimiento técnico.

Mientras tanto,También proporcionamos la máquina de cortar relacionada, máquina tratada,máquina perforada,Máquina de envoltura de película elástica, 2/3 máquina laminada de capa, Máquina de recubrimiento de educación física, etc.. Son ampliamente aplicación a la higiene,atención médica,industrial, agricultura, muebles,familiar,edificio, Campos de geotextil y filtración. Confiar en nosotros, Estamos en camino para convertirnos en su socio comercial honesto!

5.Embalaje & Envío

6.nuestro servicio

Servicio único de ventas únicas

Servicio postventa

* Soporte de consulta y consultoría

*Garantía de un año

* Las últimas tendencias de la industria

* Video de prueba de la máquina antes de la entrega

* Más solución de fabricación de bolsas de ajuste

Manual de inglés. Diagrama eléctrico

* Soporte de pruebas de muestra

* Entrenamiento de cómo instalar la máquina, Entrenamiento cómo usar

* Ver nuestra fábrica

la máquina

Sugerir soporte de diseño

*Ingenieros disponibles para maquinaria de servicio en el extranjero

7.customer reference

8.Preguntas frecuentes

1. Q:¿Cuánto tiempo tardará su ingeniero en llegar a nuestra fábrica??

A:Dentro de una semana después de todo listo (Llegada a máquina su fábrica, material no tejido,

fuente de energía, compresor de aire etc. preparado)

2. Q:¿Su ingeniero entiende inglés??

A:Nuestros ingenieros entienden un poco de inglés.. Todos nuestros ingenieros tienen más de cinco años de máquina

experiencia de instalación.

3. Q:¿Cuánto debemos cobrar por su ingeniero??

A:Debe cobrar por el costo de los boletos aéreos de nuestro ingeniero., hotel, alimento, y también su salario

800CNY un día por persona.

4. Q:¿Cuántos días tomará para la intallación??

A: Tomará 45 días, Depende del tipo de máquina.

5. Q:¿Cómo solucionamos el problema de la máquina después de que su ingeniero se vaya??

A:En términos generales, No habrá ningún problema después de terminar la instalación. En caso de que tengas alguno

problema, Puede comunicarse con nuestras ventas en cualquier momento. Nuestros ingenieros tomarán un video de solución según

Tu descripción.