Descripción del Producto

1.Perfil de la empresa:

Guanlong No Textil Technol Co., Limitado. es un fabricante profesional de PP Spunbond sin tejido de producción de telas Fujian Province. Nuestro grupo se estableció en 2005, involucrado en el campo de la máquina no tejida, tela no tejida, suministros médicos, etc.. Proporcionamos productos de alta calidad y excelentes servicios para usuarios globales..

Estamos especializados en fabricaciones(Hilado), METRO(Derretido), SS, SXS, SSS, SMS,SSMS,SMS,Ssmms,etc.. Tipo de PP(polipropileno) Hilado & Línea de producción no tejida de fundición., ISO y SGS.

Nuestra empresa ocupa más de 2,000 acres y tiene más de 60 Trabajadores especializados profesionales. Ofrecemos apoyo de ingeniero profesional, Alta eficiencia después del servicio y la superioridad del precio competitivo,y atraer clientes de todo el mundo, Exportamos a Over 20 países, incluyendo India, Vietnam, Bangladesh, Indonesia y el Medio Oriente.

Somos un proveedor confiable de los clientes con 1 Garantía de años. Podemos ofrecer una máquina de mejor calidad con ideas innovadoras y excelente después del servicio para cumplir con sus requisitos. Esperamos obtener más cooperación..

Bienvenido!!

2.Detalles del producto

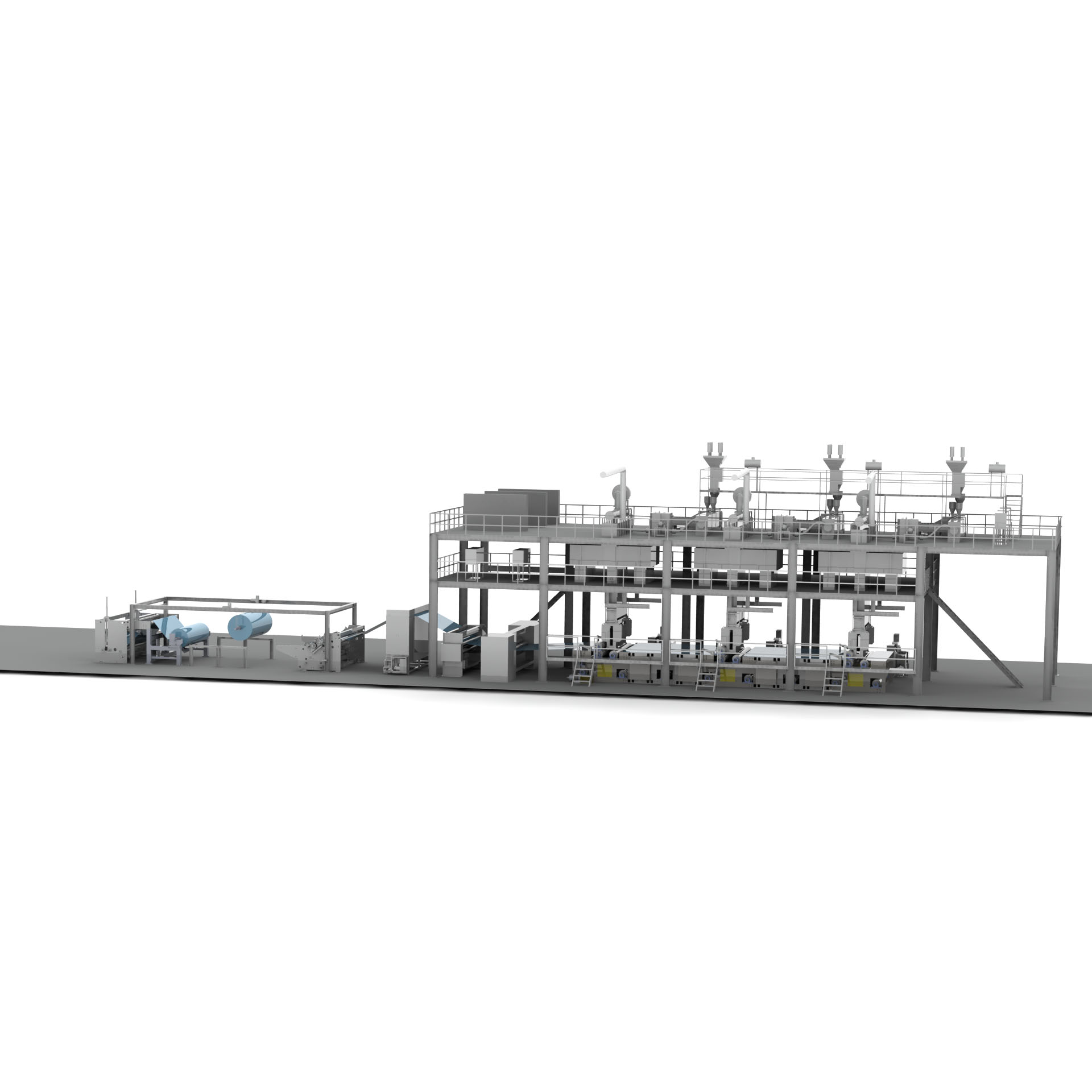

SSS1.6M Línea de producción de telas no tejidas compuestas Spunbond

Datos de tecnología principal

2-1. tipo de producto

Línea de producción de tela no tejida compuesta SSS Spunbond

1.2.Ancho del producto:1600milímetros(Ancho disponible)

1.3. Die Head Qty.:Hilado 3 sets

1.4. Negador de filamento:(S)≤1.7-2.0den (METRO)2~ 4 μ m

1.5. Rango de peso de tela:10-100g/ m2

1.6. Máximo. Velocidad de producción:350m/min

1.7.Capacidad:4500T/año

1.8.Consumo eléctrico(promedio):SSS < 800-1000 ℃/T

2-2. Descripción del Producto

1. Sobre el diseño:

La máquina no tejida SSS Spunbond adopta un gabinete de control eléctrico inteligente y un sistema de redacción de hilandería. El modo de control del sistema presenta una velocidad avanzada de frecuencia modulada de CA., comunicaciones sincronizadas totalmente digitales. Se ejecuta en alta eficiencia y bajo consumo.

Basado en las características anteriores, La máquina no tejida SSS Spunbond puede ayudar a los clientes a ahorrar mano de obra, y ampliamente compatible con diferentes altos requisitos de producciones.

2. Sobre el proceso de producción:

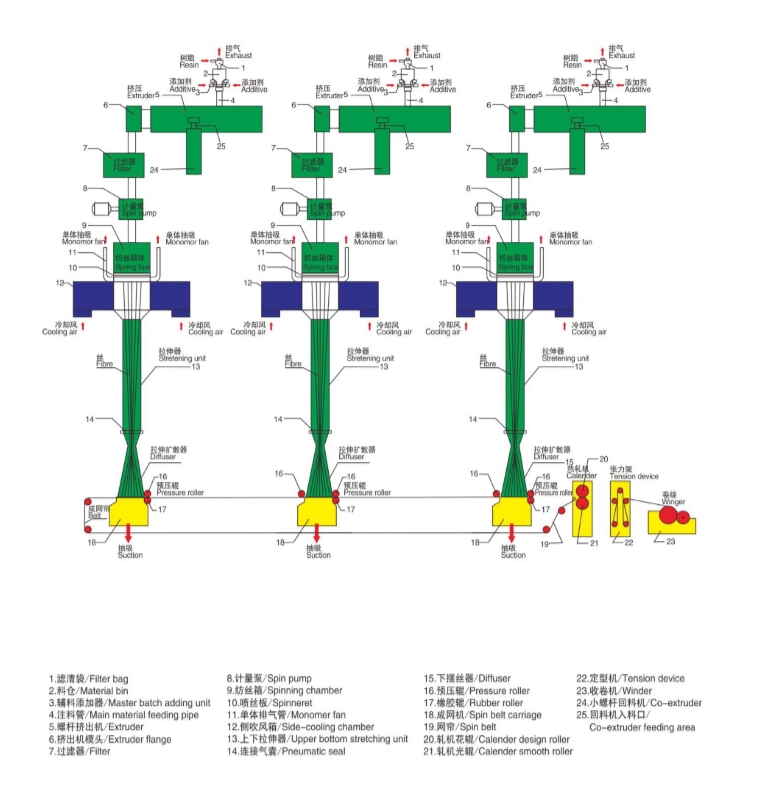

SSS Spunbond Machine no tejido es el fabricante profesional en tres capas de tela no tejida. Se fabrica para PP/PET/PLA/Bi-Component Spunbond No Woven Fabrics’ producción. Después de la entrada de materias primas., sufrir el proceso de extrusión, hilado, temple, estiramiento de aire de cierre, formación web, calendario, devanado y corte según los requisitos y luego empacado para el almacenamiento y la entrega.

3. Sobre los productos de telas.:

Porque las telas tienen mayor intensidad, mejor capacidad de respiración, y mejor sentimiento, Se usan ampliamente para varios campos, como la médica y la salud., productos para el cuidado de la belleza, productos higiénicos, cubiertas protectoras industriales y agrícolas, revestimiento de estacionamiento, etc..

4. Sobre el paquete:

Empacamos las piezas de la máquina principal en cajas de madera. Las piezas eléctricas estarán llenas de plástico y luego se empacarán en cajas de madera.. Con la estructura de acero, se empacarán en contenedores.

2-3Ventaja

La ventaja de las máquinas de fabricación de telas no tejidas HG:

1.Licuadora de materia prima de alta precisión para polipropyeno y aditivos;

2.Máquina de extrusión de alta capacidad con buenos tornillos y barril;

3.Sistema de filtración de fusión de alto rendimiento;

4.Alta velocidad con bomba de fusión alta precisa;

5.Último sistema de diseño de flujo de fusión y spinning;

6.Sistema y motores de control del PLC bien conocido;

7.Programa de operación inteligente y sistema de monitoreo;

Alimentación de materia prima PP → Fusión de extrusión → Filtrado → Medición → Spinning → Enfriamiento

→ estiramiento → propagación web → unión térmica → brote → recolección

3.Partes principales

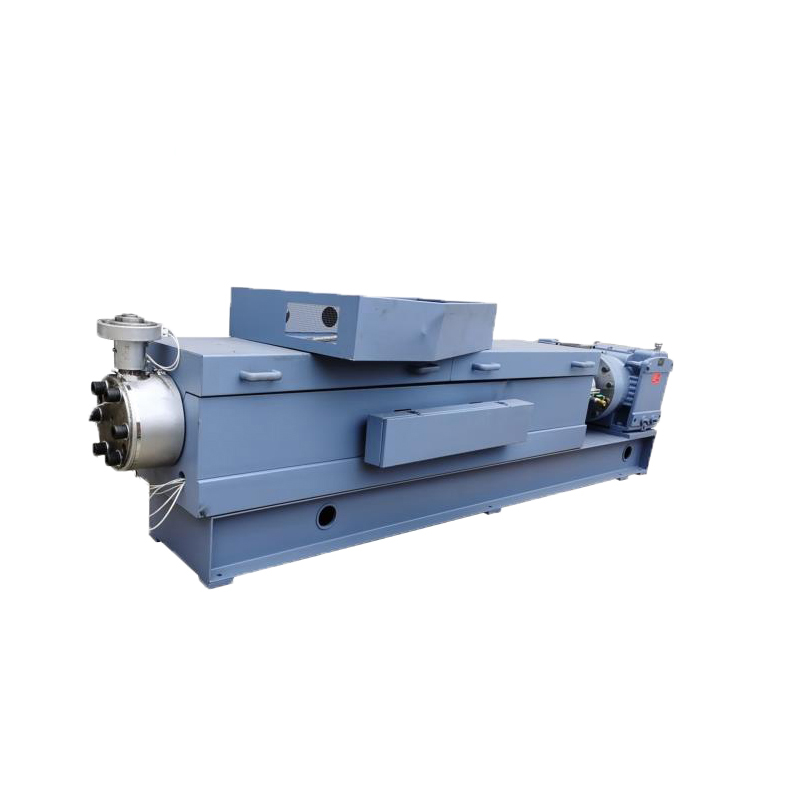

1.Presión de trabajo máxima: 16MPA

2.Temperatura de trabajo máxima: 310℃

3.Área de filtro de un solo cilindro: 0.5-19㎡

1. Relación de aspecto L/D = 30:1.

2.Diámetro del tornillo: Φ150 mm

3.Siemens Bede AC Motor 110kW, Controlador de frecuencia de Fuji

4.El cilindro espiral y el tornillo están hechos de acero nitrurro de alta resistencia, equipado con calentador de resistencia, dividido en varias zonas de calentamiento, incluyendo un conjunto completo de dispositivos de control eléctrico, incluyendo poder, control de temperatura, control de presión, etc.. Consulte la capacidad de plastificación de la parte de control eléctrico para más detalles

1.El principal rodillo de conducción está hecho de tubo de acero sin costura

2.Velocidad de corte:800-1000m/min

3. Siemens rezó AC motor, 15KW * 1 colocar, Controlador de frecuencia variable de Fuji de Japón

4.Ancho de corte mínimo: 100 milímetros

5.Diámetro máximo de devanado: 1000milímetros

6.Número de cuchillos para cortar 16 sets

7. 3 Pañales de expansión de gas de fibra de carbono

1.La velocidad del ventilador de escape es ajustable2.accesorios: GD-SM-SO2 MECHA ESTÁTICO

3.Volumen de aire total: 15000-23000 m³/ h

4.Regulador de presión del aire: Fuji Inverter (RKC-F900)

5.La potencia del ventilador es de 75kw * 1 colocar, 90KW * 1 colocar, incluyendo el tubo de escape,y el aire de succión se descarga al aire libre

6. El poder del ventilador de aire frío es de 75kw, 2sets, Se adopte el motor Siemens Bede

4.Especificación de producto

5.Requisitos de servicios públicos

1.Consumo de energía:La potencia de toda la máquina es de aproximadamente 3816kw, y el poder de trabajo es de aproximadamente 1000kw

2.El comprador debe prepararse:

① Requisitos de Workshop:longitud 70 metro * ancho 20 metro * alto 12 metro (Solo para requisitos de espacio de línea de producción, materia prima, finalizado

sala de productos, La oficina necesita tener extra)

② Suministro de potencia:380V50Hz;

Suministro de agua(agua de la ciudad),cisterna : 60-70m³(Aplicar al agua de enfriamiento

sistema de circulación)

④Provue a los trabajadores, máquina elevadora, máquina elevadora, grúa y otras herramientas de transporte

⑤Provue las materias primas requeridas

Durante la instalación y la puesta en marcha

⑥ Todos los tipos de aceite lubricante, aceite de grasa y transferencia de calor

⑦Cable del vendedor

caja eléctrica para el control eléctrico

⑧ Fundación de preparación, Placa incrustada de base y pernos de anclaje soldados en placa de base incrustada

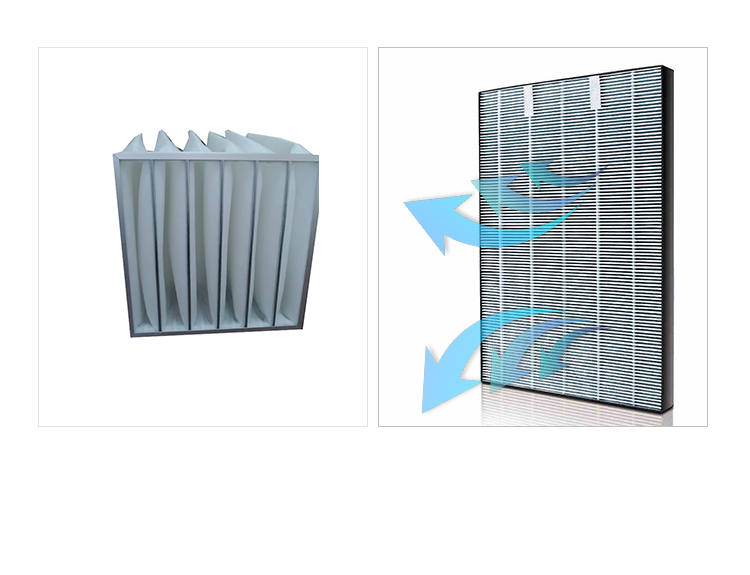

6.Solicitud

Cubiertas de jardinería, cubiertas terrestres, Carridas de protección de carreteras,Geotextiles, etc..

Filtro de mascarilla,gas,aire,líquidos, etc..

pañales para bebes y adultos: Sábanas superiores, hojas traseras, orejas, cinta, zona de aterrizaje;

Higiene femenina: almohadilla sanitaria,Sábanas superiores, alas;

Limpieza de toallitas: Cuidado del bebé, productos cosméticos, etc..

La tela no tejida puede usar diferentes tipos de fabricación de bolsas no tejidas,como la bolsa de mango no tejida, bolsa de camiseta no tejida,bolsa de caja no tejida, etc.

7.Preguntas frecuentes

1. Q:¿Cuánto tiempo tardará su ingeniero en llegar a nuestra fábrica??

A:Dentro de una semana después de todo listo (Llegada a máquina su fábrica, material no tejido,

fuente de energía, compresor de aire etc. preparado)

2. Q:¿Su ingeniero entiende inglés??

A:Nuestros ingenieros entienden un poco de inglés.. Todos nuestros ingenieros tienen más de cinco años de máquina

experiencia de instalación.

3. Q:¿Cuánto debemos cobrar por su ingeniero??

A:Debe cobrar por el costo de los boletos aéreos de nuestro ingeniero., hotel, alimento, y también su salario

800CNY un día por persona.

4. Q:¿Cuántos días tomará para la intallación??

A: Tomará 45 días, Depende del tipo de máquina.

5. Q:¿Cómo solucionamos el problema de la máquina después de que su ingeniero se vaya??

A:En términos generales, No habrá ningún problema después de terminar la instalación. En caso de que tengas alguno

problema, Puede comunicarse con nuestras ventas en cualquier momento. Nuestros ingenieros tomarán un video de solución según

Tu descripción.