The Rising Demand for SMS Spunmelt Lines

The global textile and filtration industries are undergoing a shift, and one of the most compelling trends is the rise of SMS spunmelt nonwoven production line tecnología. Combinando capas de Spunbond y Meltblown, SMS nonwoven fabrics offer an optimal balance of strength, filtración, and softness — traits highly valued in sectors from hygiene and medical to filtration media and geotextiles.

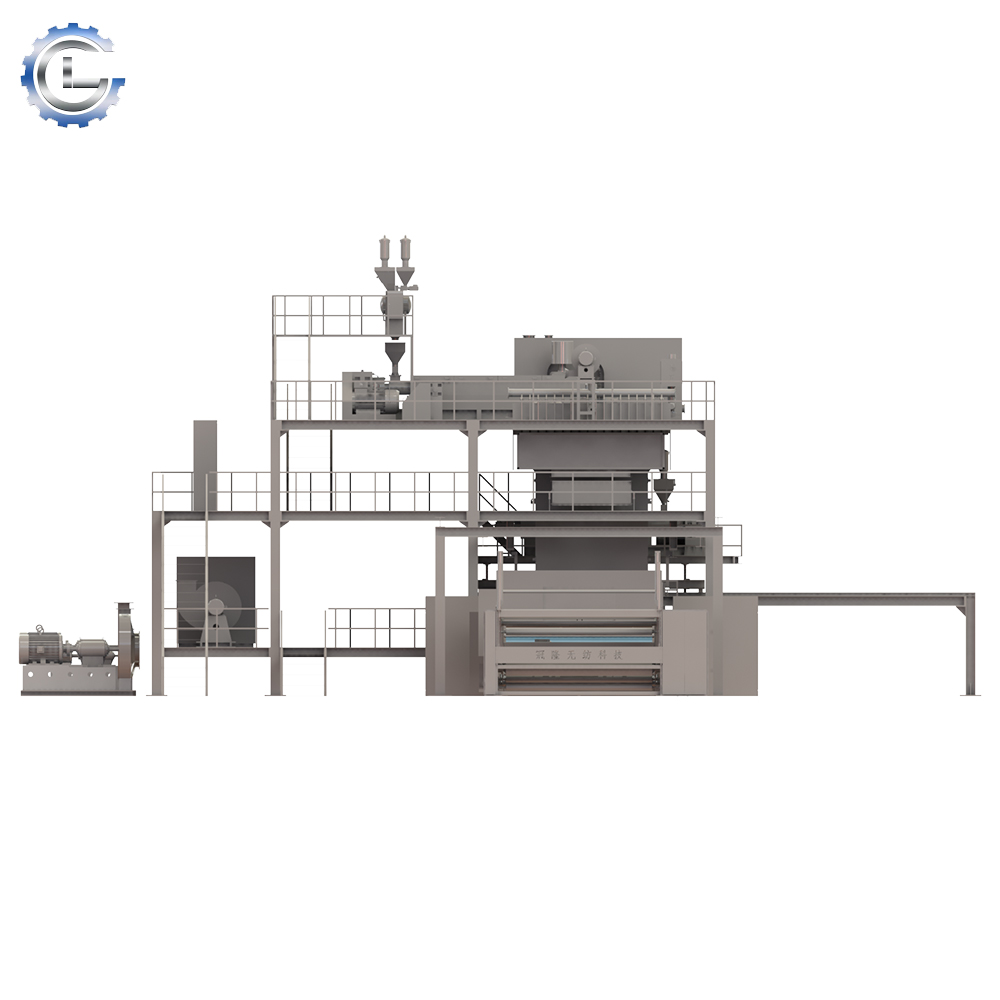

Manufacturers are increasingly adopting SMS lines to stay competitive, and companies like GLNON are at the forefront of delivering cutting-edge solutions in non woven fabric equipment. Their production lines integrate advanced process controls, modular layouts, and efficient energy usage, enabling clients to scale up quickly for high-demand orders.

What Makes SMS Spunmelt So Attractive?

One of the critical advantages of SMS nonwovens is their layered structure: spunbond layers on the outside for mechanical strength, and a meltblown layer in the middle for fine filtration. This makes the fabric ideal for uses like surgical masks, respiradores, medios de filtración, and barrier textiles. The SMS configuration allows customization of weight, fiber diameter, and layer thickness — giving manufacturers flexibility to tailor performance per application.

Además, SMS lines can run at relatively high speeds with stable output, which reduces production bottlenecks. When paired with proper maquina para telas no tejidas design and process optimization, the yield, uniformidad, and cost per meter improve significantly.

Another appeal is compatibility with downstream finishing processes such as calendaring, realce, lamination, or hydrophilic treatment. Because SMS fabrics already offer a smooth yet robust base, these post-treatments tend to integrate smoothly — further expanding application possibilities.

Challenges and Solutions in Deploying SMS Nonwoven Lines

Though attractive, deploying SMS spunmelt production lines comes with technical challenges:

- Process control & estabilidad: Ensuring uniform fiber melt flow, control de temperatura, and web formation is critical. Variations can lead to defects, web breaks, or inconsistent filtration performance. That’s why advanced sensors and control systems are essential.

- Eficiencia energética & thermal management: The meltblown component demands precise heating and cooling. Innovations such as heat recovery, optimized air flow design, and insulation help minimize energy consumption.

- Raw material quality & feed consistency: Polypropylene resin quality, melt index, and extrusion homogeneity are fundamental. Fluctuations in feedstock or melt quality can degrade output.

- Mantenimiento & uptime: Given the complexity of SMS lines, scheduled maintenance, predictive monitoring, and component access design become key to minimizing downtime.

To address these, OEMs increasingly build modular machine segments, use smart diagnostics, and design for ease of access. These improvements support long-term production stability and economic viability.

Global Market Trends and Adoption Hotspots

The adoption of SMS spunmelt lines is particularly fast in regions with growing hygiene, filtración, médico, and civil infrastructure demands. Southeast Asia, South Asia, Latin America, and parts of Africa are investing heavily in domestic capacity. Mientras tanto, mature markets in North America and Europe emphasize advanced performance, certification, and multi-layer specialty nonwovens.

Recent supply chain shifts and a renewed focus on self-reliance are also driving SMS line demand closer to end markets. Many buyers no longer want to depend solely on imports; en cambio, they are investing in local production using world-class equipment such as non woven fabric equipment models provided by companies like GLNON.

Given this landscape, forward-thinking manufacturers are looking for equipment partners that can support flexibility, high throughput, and continuous upgrade paths.

If you’re planning an upgrade, expansion, or first SMS line deployment, let GLNON help guide your journey. Contact us to explore turnkey solutions or request a tailored project quote: Get in Touch.

Company Introduction

Hench is a trusted global lab equipment supplier and industrial solutions provider, offering hydraulic presses, analytical instrumentation, sample preparation systems, and accessories tailored for research and manufacturing. With a focus on innovation, calidad, and customer support, Hench bridges the gap between laboratory development and full-scale production.