Product Description

1.Company Profile:

Guanlong Non-textile Technology Co., ltd in Quanzhou is specialized in the research,design and manufacturing of non-woven fabric production line and non-woven processing machinery since 2017.Guanlong’s predecessor is Zhejiang General Nonwoven Machine Manufacturing Company, which started in 2005. Now Guanlong has developed a series of nonwoven technological solutions like S, SS,SSS, SMS, SMMS, SSMS and SSMMS production lines and a variety of nonwoven processing machine selections.

2.Product details

2-1. product description

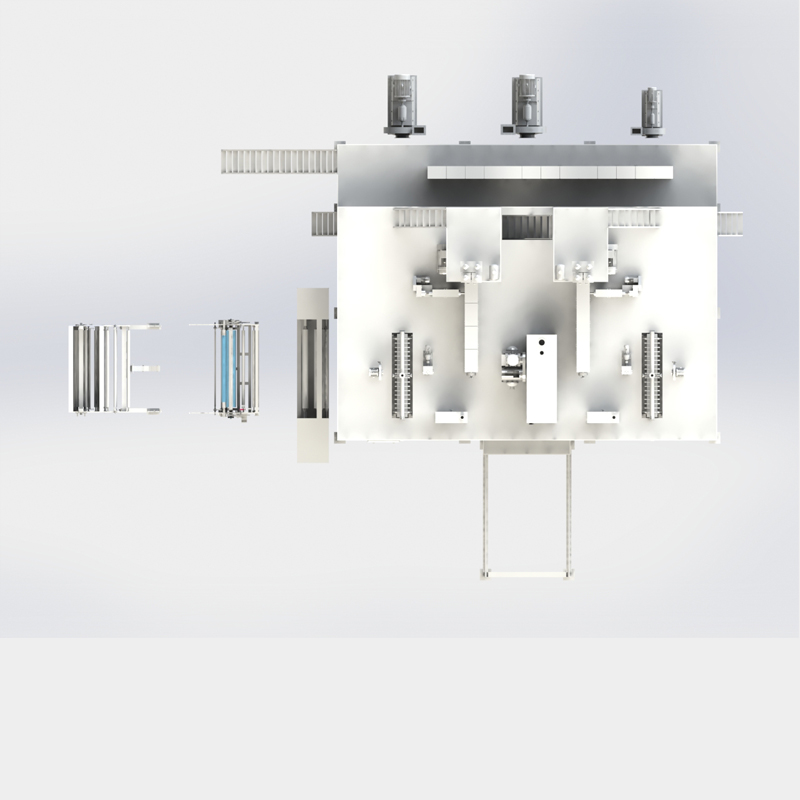

SMS Spunmelt Nonwoven Machine is well designed in three beams while combines spunbond and meltblown manufacturing technique, which is a composite line for nonwoven production.

It adopts an intelligent electrical control cabinet and spinning drafting system. The system controlling mode features in advanced AC frequency-modulated speed, fully digital synchronized communications.

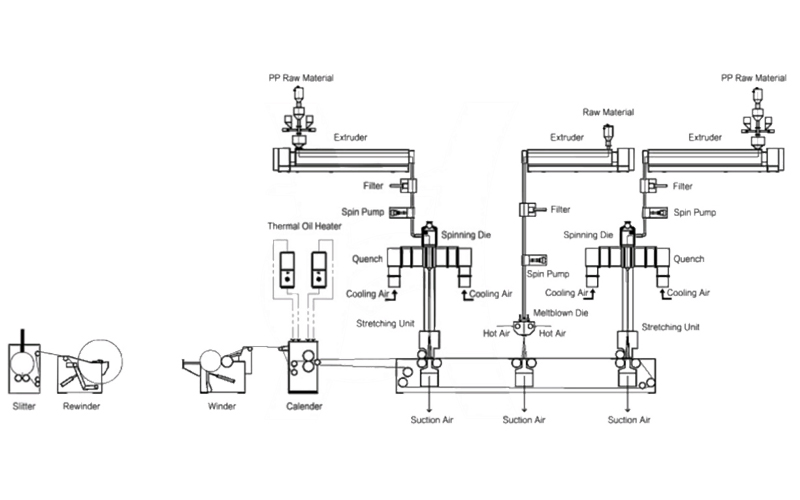

2-2.produce flow

(S)Feeding—–Extrusion Melting—–Filtering—–Metering—–

Spinning—–Cooling—–Stretching—–Web spreading—–

Thermal bonding—-Slitting—–End Products

(M)Feeding—–Extrusion Melting—–Filtering—–Metering—–Hot air Spinning—-Web formation—-Electret —-Winder—-Slitting—End Products

2-3.the specification of SMS

3.Main parts

3-1 Filter

1.Maximum working pressure: 16MPa

2.Maximum working temperature: 310℃

3.Single cylinder filter area: 0.5-19㎡

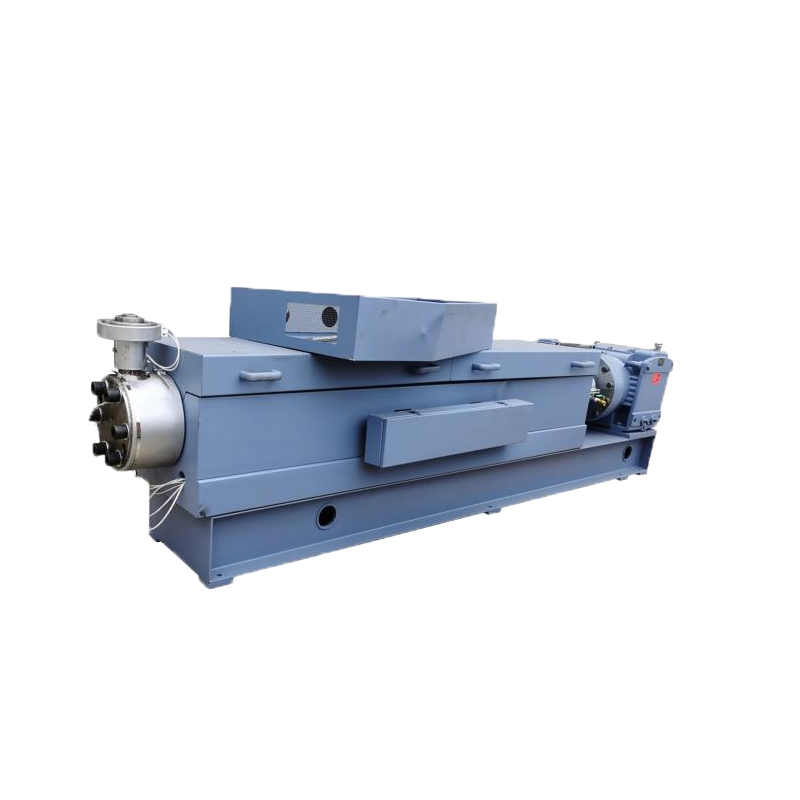

3-2 Screw extruder

1. Aspect ratio L/D=30:1.

2.Screw diameter: Φ150mm

3.Siemens Bede AC motor 110kw, Fuji frequency controller

4.The spiral cylinder and screw are made of high-strength nitriding steel, equipped with resistance heater, divided into several heating zones, including a full set of electrical control devices, including power, temperature control, pressure control, etc. see the plasticizing capacity of electric control part for details

3-3 slitting machine

1.The main driving roller is made of seamless steel tube

2.Cutting speed:800-1000m/min

3. Siemens Bede AC motor, 15kw * 1 set, Fuji variable frequency controller of Japan

4.Minimum cutting width: 100 mm

5.Maximum winding diameter: 1000mm

6.Number of slitting knives 16 sets

7. 3 carbon fiber gas expansion shafts

3-4 Fan of cold air and suction air system

1.The speed of exhaust fan is adjustable2.Accessories: GD-SM-SO2 static mixer

3.Total air volume: 15000-23000 m³/ h

4.Air pressure regulator: Fuji Inverter(RKC-F900)

5.The fan power is 75KW * 1 set, 90kW * 1 set, including the exhaust pipe, and the suction air is discharged to the outdoor

6. The power of cold air fan is 75kw, 2sets, Siemens Bede motor is adopted

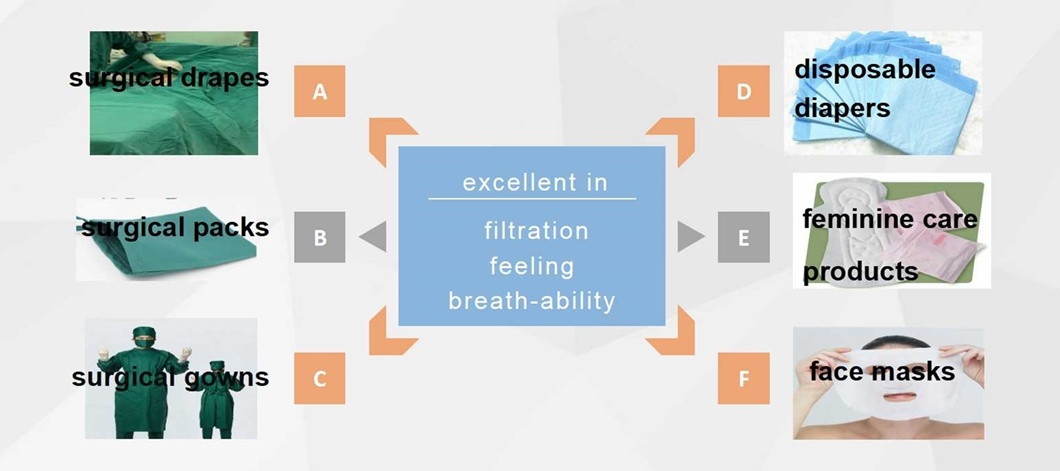

4.industry application

SMS Nonwoven fabric is featured by good breath-ability and feeling, is widely used in the hygiene or medical industry to make surgical drapes, surgical packs, surgical gowns, disposable diapers, feminine care products, face masks and so on.

5.FAQ

Q1:How many days will you finish installing?

A1:We will finish installation and training within 7-10 days.

Q1:How long is your machine’s warranty period?

A1:All our machine have one year guarantee, starting from finished installation.

Q1:How could we do if the parts broken within warranty?

A1:We would express the free replacement parts during the warranty date.

Q1:How do we solve the machine problem after your engineer leaving?

A1:Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our after sales specialist at any time.Our engineers will take a solution video according your description.