Product Description

Guanlong has been focusing on non woven fabric production Lines for 15 years. We combine global advanced technology and the demand of customers’ production, provider and customize various holistic solutions for customers. We have manufactured hundreds of full-automatic production lines for customers worldwide.

Let’s discuss about the advantages of SSMS Spunmelt Nonwoven Machine.

1. About the design:

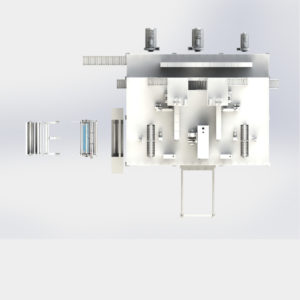

SSMS Spunmelt Nonwoven Machine is a composite line for nonwoven production which combines spunbond and meltblown manufacturing technique. SSMS Spunmelt Nonwoven Machine has four beams in production and can be customized for you according to your demands of production.

It adopts an intelligent electrical control cabinet and spinning drafting system. The system controlling mode features in advanced AC frequency-modulated speed, fully digital synchronized communications.

2. About the production process:

SSMS Spunmelt Nonwoven Machine is manufactured for PP/PET/PLA/Bi-Component spunmelt composite non-woven fabrics. After the raw materials input, go through extrusion melting, filtering, metering, spinning, cooling, stretching, web spreading, thermal bonding and cutting as per requirements and then packed for storage and delivery.

3. About the products of fabrics:

SSMS Nonwoven fabric is featured by excellent filtration, good breath-ability, and feeling, is widely used in the hygiene & medical industry to make surgical drapes, surgical packs, surgical gowns, disposable diapers, feminine care products, face masks and so on.

The main specifications of SSMS Spunmelt Nonwoven Machine:

1. The thin SMS non-woven fabric is especially suitable for the market of sanitary materials, such as sanitary napkins, sanitary pads, baby diapers, adult incontinence pants, etc.

2. Medium thickness SMS non-woven cloth, suitable for use in the medical field, for the production of surgical suits, surgical towels, surgical covers, sterilizing bandages, wound patches, plasters, etc., also suitable for the production of industrial work clothes, protective clothing, etc.

3. The thick SMS non-woven cloth is widely used as an efficient filter material for all kinds of gases and liquids, and it is also an excellent and efficient oil absorbing material, used in industrial wastewater oil removal, Marine oil cleaning and industrial dishcloth and other fields.

Melt-blown nonwovens is the most core material of mask, melt spraying cloth mainly USES polypropylene as the main material, the fiber diameter can reach 1 ~ 5 micron. The microfiber with unique capillary structure increases the number and surface area of fiber per unit area, so that the melt spray cloth has good filtering, shielding, insulation and oil absorption.

Melt-blown nonwovens can be used for air, liquid filtration materials, isolation materials, absorption materials, mask materials, warm materials, oil absorption materials and wiping cloth and other fields.