Como demanda por produtos de higiene, Materiais médicos, E as embalagens ecológicas continuam a surgir em todo o mundo, o papel de máquinas não tecidas na fabricação moderna têxtil nunca foi tão crítica. No coração desta transformação industrial está Guanlong, um fabricante reconhecido globalmente de alto desempenho Máquinas de tecido não tecidas Projetado para fornecer taxa de transferência excepcional, consistência do material, e eficiência de custo.

Com mais de uma década de experiência em máquinas de fibra, Guanlong fornece soluções abrangentes para os fabricantes que buscam otimizar as operações, Aumente a automação, e fique à frente em um mercado cada vez mais competitivo.

O que faz uma ótima máquina de tecido não tecido?

A produção não tecida é tanto sobre velocidade e estabilidade quanto sobre adaptabilidade. Se você está produzindo tecidos médicos de uso único ou geotêxteis duráveis, a confiabilidade do seu Máquina de tecido não tecida é essencial para manter a qualidade e atender aos prazos de entrega apertados.

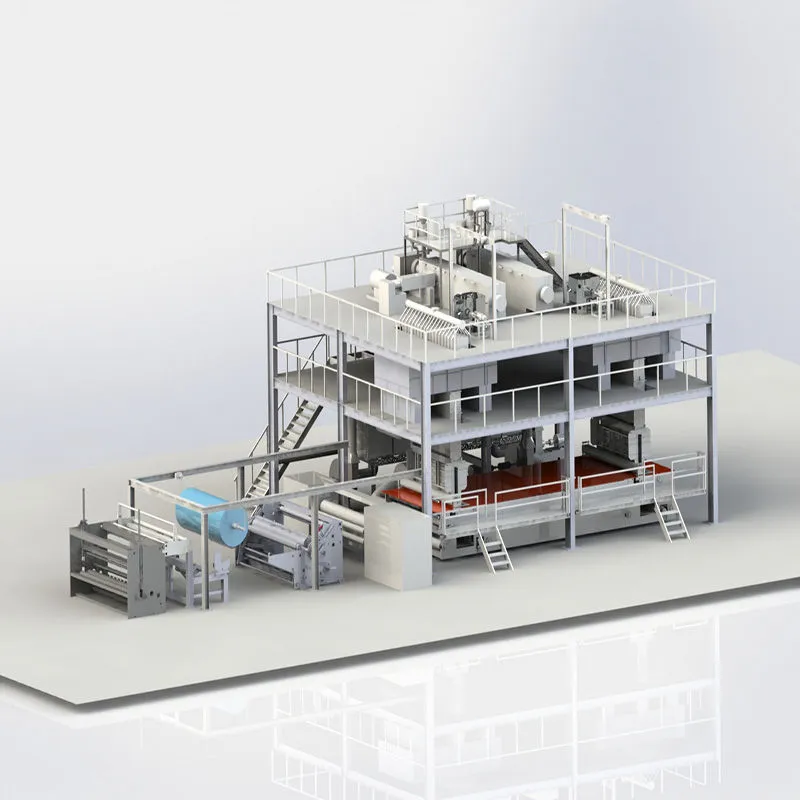

As máquinas guanlong são construídas para exceder as expectativas da indústria, integrando:

- Controles avançados de temperatura e pressão

- Sistemas de monitoramento e feedback em tempo real

- Montagem modular para facilitar atualizações e personalização

- Sistemas automáticos de controle de tensão e enrolamento de tecido

Esses recursos não apenas melhoram a eficiência da produção, mas também minimizam o desperdício e reduzem o tempo de inatividade.

PP Spunbond Nonwoven Making Machine: A solução principal

Entre as ofertas mais populares de Guanlong está o PP Spunbond Nonwoven Making Machine- Uma escolha ideal para aplicações em higiene, agricultura, embalagem, e construção.

Os principais recursos incluem:

- Configurações de feixe múltipla (solteiro, dobro, ou vigas triplas)

- Larguras de saída de 1,6m a 3,2m

- Spinnerets e sistemas de refrigeração de alta velocidade

- Controle sincronizado da extrusão, alongamento, formação da web, e vínculo

O resultado? Um fluxo de produção sem costura que oferece densidade uniforme de tecido, alta resistência à tração, e uma sensação de mão suave - qualidades essenciais para vestidos médicos, fraldas para bebês, sacolas de compras, e mais.

Versatilidade entre aplicações e materiais

Guanlong's máquinas não tecidas são capazes de lidar com uma grande variedade de polímeros, incluindo polipropileno (PP), poliéster (BICHO DE ESTIMAÇÃO), ácido polilático (PLA), e outros materiais biodegradáveis - alinhando com demandas ambientais crescentes na indústria têxtil.

Os clientes implementaram com sucesso essas máquinas na fabricação:

- Máscaras cirúrgicas e bonés médicos

- Coverlls protetores e folhas descartáveis

- Tampas de colheita e tecidos de controle de ervas daninhas

- Mídia de filtragem aérea e camadas de isolamento industrial

Com adaptabilidade embutida, Os usuários podem alternar entre os tipos de produtos ou integrar funções de agregação de valor, como laminação, gravação em relevo, ou impressão.

Pegada global com suporte local

Guanlong ganhou seu lugar como líder fabricante de máquinas não tecidas não apenas produzindo máquinas confiáveis, mas também apoiando clientes em todo 30+ países com serviços proibidos.

Os clientes se beneficiam de:

- Instalação e treinamento de especialistas

- 24/7 Solução de problemas remotos

- Peças de reposição em estoque e despacho rápido

- Layout da planta personalizado e planejamento de produção

A empresa também oferece testes piloto e visitas de fábrica, permitindo que os clientes validem o desempenho da máquina e configure as configurações específicas para suas necessidades de mercado.

Soluções sustentáveis para uma economia circular

Como o mercado global gira em direção à produção mais verde, Guanlong está comprometido com a sustentabilidade. Isso é Máquinas de tecido não tecidas são projetados com componentes com eficiência energética, queimadores de baixa emissão, e sistemas de reciclagem para acabamentos e fora da borda.

Adicionalmente, A integração do PLA e outros polímeros de base biológica nas opções de máquinas de Guanllong reflete um passo consciente em direção a ciclos circulares de produção e materiais ecológicos.