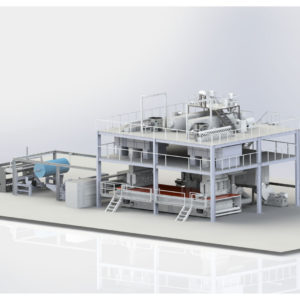

Máquina PP SS Spunbond

A PP SS (Polipropileno Spunbond) Machine é um tipo de máquina de produção de tecido não tecido usada para criar tecidos a partir de resina de polipropileno. O processo envolve a fusão e a extrusão da resina de polipropileno, que é então girado em filamentos, e posteriormente estabelecido em uma formação semelhante à Web para criar um tecido não tecido.

O “SS” em PP SS Machine significa “Spunbond/Spunbond,” que se refere à formação da web de camadas duplas criada pela máquina. Este tipo de tecido não tecido é comumente usado em uma variedade de aplicações, inclusive como um peso leve, material respirável para vestidos médicos descartáveis, máscaras faciais, e outro equipamento de proteção, bem como para revestimentos agrícolas, geotêxteis, e outras aplicações industriais.

As máquinas PP SS normalmente consistem em vários componentes -chave, incluindo uma extrusora para derreter e girar a resina de polipropileno, um feixe de giro para direcionar os filamentos para uma correia transportadora em movimento, e um sistema de ligação para fundir os filamentos em uma web coesa. A máquina também pode incluir equipamentos adicionais para cortar, enrolamento, e terminando o tecido.

Geral, As máquinas PP SS desempenham um papel importante na produção de tecidos não tecidos, que são amplamente utilizados em uma variedade de indústrias e aplicações.

Mostrando tudo 7 Resultados

-

Vigas duplas ss 100% PP Máquina de tecido não tecida Spunbond para tecido SS de Bond Spun

-

SS Bancos duplos de alta capacidade e velocidade Spunbond não tecida Máquina de tecido

-

A maioria de tela não tecida avançada dos SS que faz a linha de produção quente dos feixes dobro dos SS da venda da máquina

-

2400MM MM SS Linha de produção de pano não arborizada

-

Máquina de fabricação de tecido não tecida SS Ss Spunbonded

-

Linha de produção de tecido não tecido duplo

-

PP SS SPUNBOND MACHINE DE FAZENDO DE TERCO NÃO TERRO