Оборудование для производства нетканых материалов, полученных методом выдувания из расплава, стало незаменимым в различных отраслях промышленности: от медицинских материалов и фильтрации воздуха до армирования геотекстиля и промышленных сорбентов.. Для B2B-покупателей, решение инвестировать в технологию производства методом мельтблаун больше не ограничивается расширением мощностей.; речь идет об обеспечении долгосрочной конкурентоспособности, повышение точности продукта, и повышение устойчивости цепочки поставок.

В этом подробном руководстве рассматриваются основы, основные конфигурации машины, производственный рабочий процесс, и критические факторы, которые производители должны оценить, прежде чем войти в сектор нетканых материалов, полученных методом экструзии из расплава, или модернизировать его..

Понимание технологии мелтблауна и ее промышленного значения

Производство нетканых материалов методом выдувания из расплава — это узкоспециализированный процесс, в котором используется высокоскоростной горячий воздух для растяжения и размягчения расплава полимера до получения ультратонких волокон.. Эти волокна образуют сетчатую структуру с исключительными фильтрационными свойствами., делает ткань, полученную методом выдувания из расплава, незаменимой во многих областях применения, ориентированных на производительность..

Почему оборудование, полученное методом выдувания из расплава, важно для B2B-покупателей

• Контроль тонкости волокон обеспечивает точную степень фильтрации.

• Автоматизация повышает стабильность производства и снижает зависимость от рабочей силы.

• Высокая однородность поддерживает такие сложные применения, как фильтрующий материал N95.

• Производство на месте снижает зависимость от нестабильных глобальных сетей поставок.

Сегодняшние покупатели также полагаются на настройка линии нетканого материала для адаптации ширины машины, конструкции штампов, фильтрационные характеристики, и скорость производства в соответствии с конкретными потребностями отрасли. Правильная конфигурация напрямую влияет на рентабельность инвестиций в эксплуатацию., производительность продукта, и успех на вторичном рынке.

Узнайте больше в этом руководстве: настройка линии нетканого материала

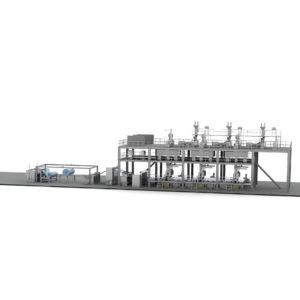

Основные компоненты оборудования для производства нетканых материалов из расплава

Современная линия мельтблауна представляет собой сложную интеграцию механической точности., полимерная инженерия, и интеллектуальные системы управления. Покупатели B2B получают выгоду от понимания основных компонентов, которые определяют качество продукции и энергоэффективность..

1. Блок подачи и экструзии полимеров

Экструдер плавит и сжимает необработанный полипропилен или специальные полимеры.. Стабильный контроль температуры имеет решающее значение для достижения постоянного диаметра волокна..

2. Сборка матрицы из расплава

Часто считается сердцем машины, матрица определяет тонкость волокна и однородность ткани. Такие параметры, как плотность дырок, ширина матрицы, и калибровка воздушного зазора существенно влияют на характеристики конечного продукта.

3. Система горячего воздуха

Высокоскоростной, потоки нагретого воздуха растягивают полимер в ультратонкие волокна. Покупатели должны оценить постоянство давления воздуха., потребление энергии, и термическая стабильность.

4. Коллекторная система

Волокнистое полотно укладывается на движущееся сито.. Точность механизмов всасывания и укладки полотна определяет однородность ткани и прочность на разрыв..

5. Намоточное устройство и окончательная обработка

Автоматизация сокращает время простоев и поддерживает непрерывный производственный ритм..

Для промышленного применения, например, геотекстиля., оборудование для выдувания из расплава также часто интегрируется с полным нетканая машина для производства геотекстиля, создание многоуровневой производственной экосистемы, поддерживающей дренажные слои, армирующие слои, и решения для стабилизации грунта. Узнайте больше здесь: нетканая машина для производства геотекстиля

Ключевые области применения, определяющие рыночный спрос на нетканые материалы, полученные методом выдувания из расплава

Медицинская фильтрация и СИЗ

Нетканый материал, полученный методом выдувания из расплава, остается золотым стандартом для фильтрующих слоев респираторов., сердцевины хирургической маски, и очистка воздуха медицинского уровня.

Фильтрация воздуха и жидкости

Точный контроль волокон делает ткань, выдутую из расплава, идеальной для фильтров систем отопления, вентиляции и кондиционирования воздуха., системы разделения нефти и воды, и пылесборники большой емкости.

Промышленные сорбенты

Ультратонкие волокнистые структуры повышают эффективность адсорбции, изготовление прокладок из расплава, необходимых для очистки разливов нефти и промышленного обслуживания.

Геотекстиль и строительство

Несмотря на то, что спанбонд доминирует среди сверхпрочного геотекстиля, Слои, полученные методом мельтблауна, улучшают фильтрационные и дренажные характеристики композитного геотекстиля..

Материалы для сепараторов аккумуляторов

Развивающиеся рынки электромобилей все чаще используют сепараторы, полученные методом выдувания из расплава, при производстве литий-ионных элементов., создание новых траекторий спроса для производителей.

Что покупатели B2B должны оценить перед инвестированием

Инвестирование в оборудование, полученное методом выдувания из расплава, является решением, требующим высоких ставок.. Производители B2B должны тщательно оценить следующее::

1. Позиционирование продукта и требуемая степень фильтрации

Подумайте, нужна ли вам фильтрация N95/N99., промышленные сорбенты, или слои нетканого материала для композитных тканей. Для каждого требуются разные конфигурации машины..

2. Выходная мощность и ширина линии

Типичная линия мелтблауна имеет ширину от 600 мм до 3200 мм.. Большая ширина способствует массовому производству., но требуют больших инвестиций в автоматизацию и управление температурой.

3. Совместимость сырья

Полипропилен входит в стандартную комплектацию., но рынки для ТПУ, Плата, и производство высокоэффективных полимеров растет. Убедитесь, что ваше оборудование поддерживает их, если вы нацелены на новые приложения..

4. Затраты на техническое обслуживание и эксплуатацию

Оценить механизмы очистки матрицы, циклы замены фильтров, и наличие запчастей.

5. Уровень автоматизации

Современные покупатели ищут:

• Мониторинг с помощью ПЛК

• Автоматическое управление намоткой

• Точная балансировка температуры матрицы.

• Энергоэффективные воздушные системы

Правильный уровень автоматизации напрямую влияет на конкурентное преимущество..

Как оборудование, полученное методом выдувания из расплава, повышает прибыльность и расширение рынка

Хорошо спроектированная линия выдувания из расплава помогает производителям:

• Сокращение затрат на аутсорсинг

• Захват высокодоходных рынков фильтрации

• Укрепить контроль над цепочкой поставок.

• Расширить портфолио продуктов.

• Повышение гибкости доставки для международных покупателей.

Тем временем, модульная архитектура линии поддерживает поэтапное расширение, позволяя предприятиям масштабироваться без значительной реструктуризации завода.

Производители, поставляющие фильтрацию, гигиена, автомобильный, геотекстиль, и энергетические рынки сочтут оборудование, полученное методом выдувания из расплава, стратегическим долгосрочным активом для повышения эксплуатационной устойчивости и инноваций..

О Гуаньлуне

Guanlong — ведущий производитель оборудования для производства нетканых материалов., специализирующийся на выдувании из расплава, спанбонд, SMS, и полностью индивидуальные линии по производству нетканых материалов. Обладая глубокими инженерными знаниями, передовые производственные возможности, и приверженность высокопроизводительным промышленным решениям, Guanlong поддерживает мировых производителей в области фильтрации, геотекстиль, гигиена, и рынки промышленных материалов. От прецизионных систем мельтблауна до настройки линий по производству нетканых материалов «под ключ»., Guanlong предлагает надежную технологию, которая помогает B2B-клиентам повысить эффективность, расширить присутствие на рынке, и добиться стабильного качества продукции.