В нетканой текстильной промышленности, Технологии Spunbond и Puleblown служат основой многих важных продуктов - от медицинских масок и фильтрационных слоев до гигиены и сельскохозяйственных материалов. Однако, оборудование, используемое для производства этих тканей, не является взаимозаменяемым.. Понимание ключевых различий между Spunbond нетканая ткань а машина для выдувания ткани из расплава жизненно важна для производителей, стремящихся оптимизировать производство и удовлетворить разнообразные потребности рынка.. В Спанлонг Спантех, ведущий производитель высокоточного нетканого оборудования, эти различия четко определены и стратегически развиты для удовлетворения глобального спроса..

Что такое ткани спанбонд и мелтблаун??

Процессы спанбонд и мелтблаун подпадают под более широкую категорию производства нетканых материалов., где волокна соединены вместе без плетения или вязания.. Однако, они служат разным целям:

- Спанбонд ткани прочные, дышащий, и подходит для структурных слоев

- Мельтблаун ткани мягкие, плотный, и используется для тонкой фильтрации

Каждый требует определенного Нетканое оборудование адаптированный к его функции и свойствам волокна.

Основные различия между машинами для спанбонда и мелтблауна

| Особенность | Машина для производства нетканых материалов спанбонд | Машина для производства выдувной ткани из расплава |

|---|---|---|

| Диаметр волокна | 15–40 микрон | 1–5 микрон |

| Требование к давлению воздуха | Ниже | Система горячего воздуха высокого давления |

| Фокус на приложениях | Гигиенический задний лист, упаковка, сельское хозяйство | Фильтрация, маски, поглощение масла |

| Пропускная способность | Выше (большие объемы) | Ниже (более тонкая структура волокон, более медленная скорость) |

| Конфигурация линии | Обычно является частью многослойных композитных систем. (SMS) | Автономно или интегрировано в многоуровневые системы. |

Спанлонг Спантех предлагает специализированные линии для обеих технологий, каждый оптимизирован для повышения эффективности, стабильность, и долгосрочная производительность.

Когда выбирать какую машину?

Выбор между машиной для производства нетканого материала спанбонд и машина для производства выдувной ткани зависит от вашего конечного продукта:

- Выбирать спанбонд для продуктов, требующих прочности, долговечность, и массовое производство (НАПРИМЕР., Сумки для покупок, хирургические халаты, покровы урожая).

- Выбирать выдутый из расплава для применений, требующих тонкой фильтрации и мягких на ощупь поверхностей (НАПРИМЕР., Маски N95, воздушные фильтры, сантехнические материалы).

Для клиентов, ищущих оба, Spunlong Spuntech предоставляет интегрированные линии SMS или SMMS., объединение нескольких функций в единую систему.

Зачем инвестировать в специализированное нетканое оборудование?

Использование правильной машины повышает:

- Качество продукции: Равномерное распределение волокон и прочность сцепления

- Эффективность производства: Меньше дефектов, лучшее использование энергии

- Гибкость рынка: Возможность переключения или масштабирования линий для разных приложений.

- Соответствие нормативным требованиям: Особенно важно в производстве медицинского назначения.

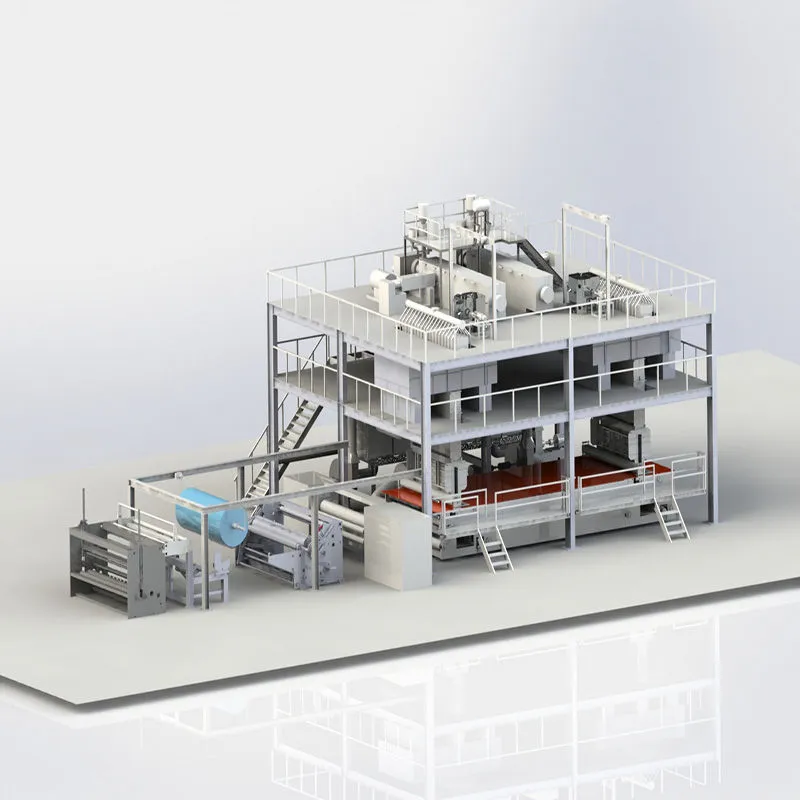

Полный набор оборудования Spunlong Spuntech для производства нетканых материалов обеспечивает бесперебойную работу на всех этапах — от подачи полимера и экструзии до формирования и намотки полотна..

Спанлонг Спантех: Один поставщик, Несколько технологий

Как надежный отраслевой партнер, Spunlong Spuntech поставляет больше, чем просто машины — она предлагает комплексные решения для производства нетканых материалов.. Нужна ли вам высокопроизводительная машина для производства нетканых материалов спанбонд или машина для производства ткани из расплава с точным управлением?, Спанлонг предлагает:

- Модульная конструкция линии для индивидуальной планировки завода

- ПЛК & Автоматизированные системы управления HMI

- Быстрая установка и послепродажная поддержка.

- Мировой опыт в области гигиены, фильтрация, и упаковочная промышленность

С растущей клиентской базой по всей Азии, Европа, и Америки, Spunlong продолжает устанавливать стандарты качества и надежности в производстве нетканых материалов..

Сделайте правильные инвестиции в производство нетканых материалов

Разница между машинами для спанбонда и мелтблауна не только техническая, но и стратегическая.. Выберите правильное решение для целей вашего продукта, воспользовавшись опытом Spunlong Spuntech.. Свяжитесь с нами сегодня, чтобы ознакомиться с полным спектром нашего современного оборудования для производства нетканых материалов и индивидуальных производственных линий..