للمصنعين الصناعيين ومشتري الآلات غير المنسوجة, استخدام PET المعاد تدويره (rPET) هو اتجاه متزايد يهدف إلى تحسين الاستدامة وخفض تكاليف الإنتاج. والسؤال الذي يواجهه العديد من صناع القرار الصناعي هو: can recycled PET be effectively used for spunbond or needle-punch nonwoven lines without compromising fabric quality or production efficiency?

The short answer is yes, but successful implementation requires understanding the properties of recycled PET, processing requirements, and machinery considerations. في هذه المقالة, we will explore the feasibility, technical challenges, benefits, and equipment adaptations for using recycled PET in spunbond and needle-punch nonwoven lines.

Understanding Recycled PET

What Is Recycled PET?

Recycled PET is derived from post-consumer or post-industrial PET materials, such as bottles, packaging films, or industrial scraps. These materials are cleaned, shredded, and re-extruded into pellets suitable for fiber production. Recycled PET offers significant environmental benefits by reducing landfill waste and conserving raw materials.

Key Properties of rPET

The performance of recycled PET can vary depending on the source and recycling process. Important properties for nonwoven production include:

- Melt flow index (MFI): Determines the ease of extrusion for spunbond lines.

- Molecular weight: Affects fiber strength and elongation.

- Moisture content: High moisture can cause fiber defects or processing instability.

- Color consistency: Important for uniform fabric appearance.

Properly processed rPET with controlled quality parameters can be used in nonwoven production without sacrificing performance.

Feasibility in Spunbond Lines

Adapting Spunbond Nonwoven Machines

Spunbond lines require precise extrusion and fiber drawing conditions. Recycled PET typically has slightly lower molecular weight than virgin PET, which may affect filament strength. To adapt:

- Adjust extrusion temperature and speed to accommodate rPET flow properties.

- Monitor fiber stretching and orientation to maintain tensile strength.

- Use advanced آلات صنع الأقمشة غير المنسوجة سبونبوند designed to handle material variability.

With proper adjustments, rPET can be spun into continuous filaments suitable for medical, صحة, or industrial nonwovens.

Performance Considerations

- Fabrics may require slightly higher bonding temperatures to achieve optimal web consolidation.

- Uniformity in fiber diameter is crucial for mechanical strength and fabric appearance.

- rPET spunbond fabrics are suitable for lightweight to medium-weight applications such as protective garments, أقنعة, والتعبئة والتغليف.

Feasibility in Needle-Punch Lines

Needle-Punch Process Overview

Needle-punch nonwoven lines create fabrics by mechanically interlocking fibers using barbed needles. This process can accommodate a wide range of fiber types, including recycled materials.

- rPET fibers can be used either as a primary fiber or blended with virgin PET to improve mechanical properties.

- Needle-punching does not require high filament continuity, making it more forgiving than spunbond lines.

Performance Optimization

- Control fiber length to prevent fiber breakage or mat inconsistency.

- Blend rPET with virgin PET to achieve desired tensile strength and thickness.

- Maintain consistent moisture and thermal conditions during carding, تشكيل الويب, and needling.

Needle-punch nonwoven fabrics made with rPET are commonly used in المنسوجات الأرضية, وسائط الترشيح, والديكورات الداخلية للسيارات.

Benefits of Using rPET

Environmental Impact

- Reduces plastic waste by reusing post-consumer materials.

- Lowers carbon footprint compared to virgin PET production.

- Supports corporate sustainability initiatives and compliance with environmental regulations.

Cost Advantages

- Recycled PET is typically less expensive than virgin PET.

- Reduced raw material costs contribute to lower production expenses, particularly for high-volume applications.

Technical Flexibility

- rPET can be blended with virgin PET to tailor fiber properties.

- Compatible with both spunbond and needle-punch lines when machinery is properly calibrated.

Equipment and Processing Considerations

Key Machine Adjustments

- Monitor extrusion temperatures and screw speed to compensate for rPET variability.

- Ensure advanced آلات Spunbond غير المنسوجة أو ماكينات الأقمشة غير المنسوجة have precise tension and speed control.

- Implement moisture control systems to avoid filament defects or fiber entanglement.

Quality Control Measures

- Conduct regular tests for قوة الشد, استطالة, and fiber diameter.

- Maintain consistent web formation and thermal bonding conditions.

- Blend ratios should be optimized for end-use requirements.

التطبيقات الصناعية

Spunbond Fabrics

- المنتجات الطبية والنظافة: أقنعة, العباءات الجراحية, مناديل

- Disposable packaging: أكياس, الحقائب, and liners

- Agricultural fabrics: Crop covers and protection sheets

Needle-Punch Fabrics

- المنسوجات الأرضية: تثبيت التربة, السيطرة على التآكل, drainage mats

- الترشيح الصناعي: مرشحات الهواء والسوائل

- السيارات: العزل, carpeting, بطانات الجذع

| Application Type | rPET Suitability | Notes |

|---|---|---|

| سبونبوند | Medium | Best for lightweight and disposable fabrics |

| Needle-Punch | عالي | Can handle heavier, industrial-grade applications |

Operational Tips for Using rPET

- Blend with virgin PET for applications requiring high mechanical strength.

- Pre-dry rPET pellets to maintain extrusion stability.

- Adjust bonding and calendering parameters to achieve uniform fabric quality.

- Perform regular equipment maintenance to prevent fiber contamination and ensure consistent output.

For expert guidance on configuring your production lines for recycled PET, اتصل بفريقنا for tailored support and technical recommendations.

التعليمات

1. Can 100% recycled PET be used in spunbond lines?

نعم, but careful control of extrusion, درجة حرارة, and filament drawing is required to maintain fiber strength and uniformity. Many manufacturers prefer blending with virgin PET for high-performance applications.

2. Does rPET affect needle-punch fabric quality?

Recycled PET can be used effectively, particularly in needle-punch lines. Blending with virgin PET can enhance mechanical properties if needed.

3. Are there environmental benefits to using rPET?

نعم, using recycled PET reduces plastic waste, lowers carbon footprint, and supports sustainability initiatives.

4. Does machinery need modification to process rPET?

Machines must be calibrated for extrusion temperatures, tension control, and moisture levels to handle recycled PET effectively.

حول قوان لونغ

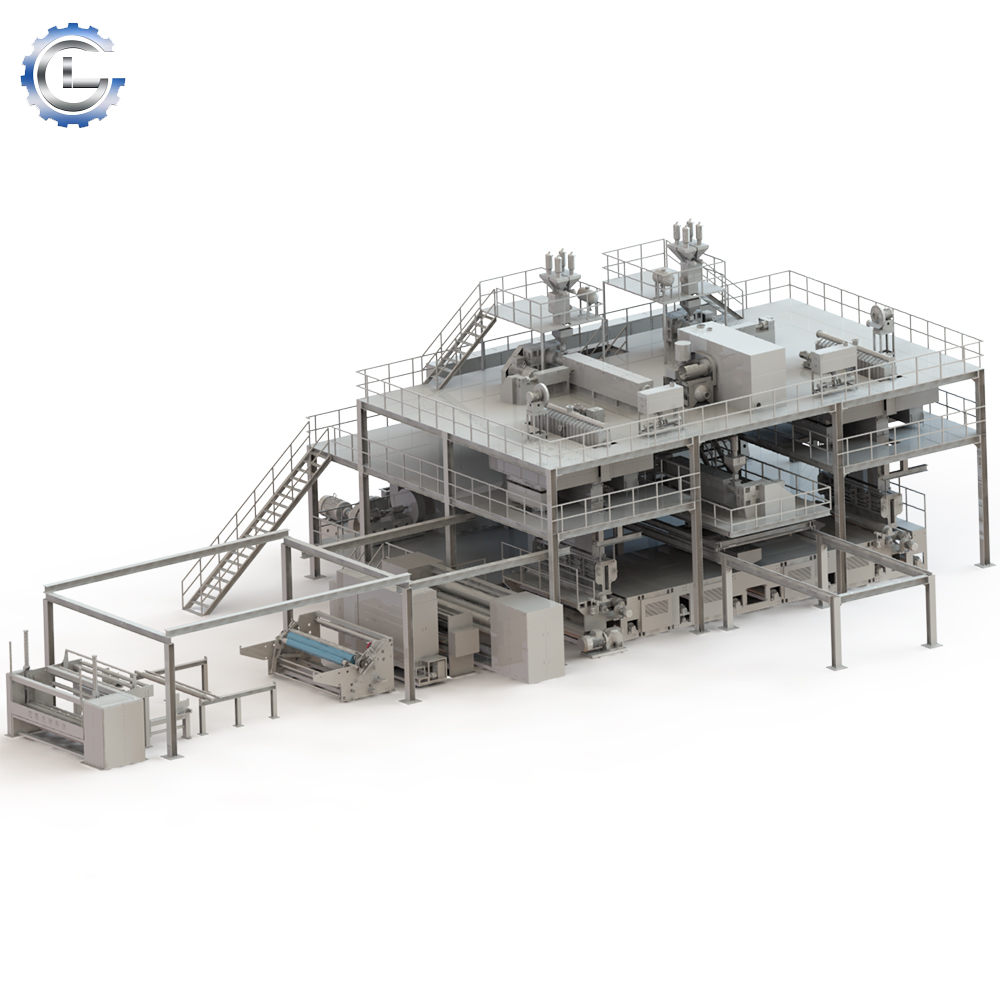

قوان لونغ is a leading non woven fabric machine manufacturer specializing in high-performance spunbond and needle-punch nonwoven machinery. Our spunbond nonwoven fabric making machine and spunbond nonwoven machine are engineered to handle both virgin and recycled PET materials with precision, consistency, والكفاءة. Guanlong supports industrial clients worldwide with reliable, customizable solutions for sustainable nonwoven production, combining environmental responsibility with high operational performance.

مراجع

- البولي إيثيلين تيريفثاليت - ويكيبيديا

https://en.wikipedia.org/wiki/Polyethylene_terephthalate - Recycled Plastics in Nonwoven Production – ScienceDirect

https://www.sciencedirect.com/topics/engineering/recycled-polymer-nonwoven - Spunbond Technology – Wikipedia

https://en.wikipedia.org/wiki/Spunbond - Needle-Punch Nonwoven Fabrics – Textile Learner

https://www.textilelearner.net/needle-punched-nonwoven-fabric/