Feb 24, 2026 | News

How to optimize material usage and reduce waste in nonwoven production is not simply a technical adjustment, it is a strategic decision that directly impacts profitability, product consistency, and long term competitiveness. The answer lies in combining precise...

Feb 18, 2026 | News

For industrial manufacturers and nonwoven machinery buyers, the use of recycled PET (rPET) is a growing trend aimed at improving sustainability and reducing production costs. The question many industrial decision-makers face is: can recycled PET be effectively used...

Feb 11, 2026 | News

For manufacturers and industrial buyers, understanding the differences between PP (polypropylene) and PET (polyethylene terephthalate) nonwoven lines is crucial when selecting the right equipment for their production needs. PP and PET nonwoven fabrics differ in...

Feb 5, 2026 | News

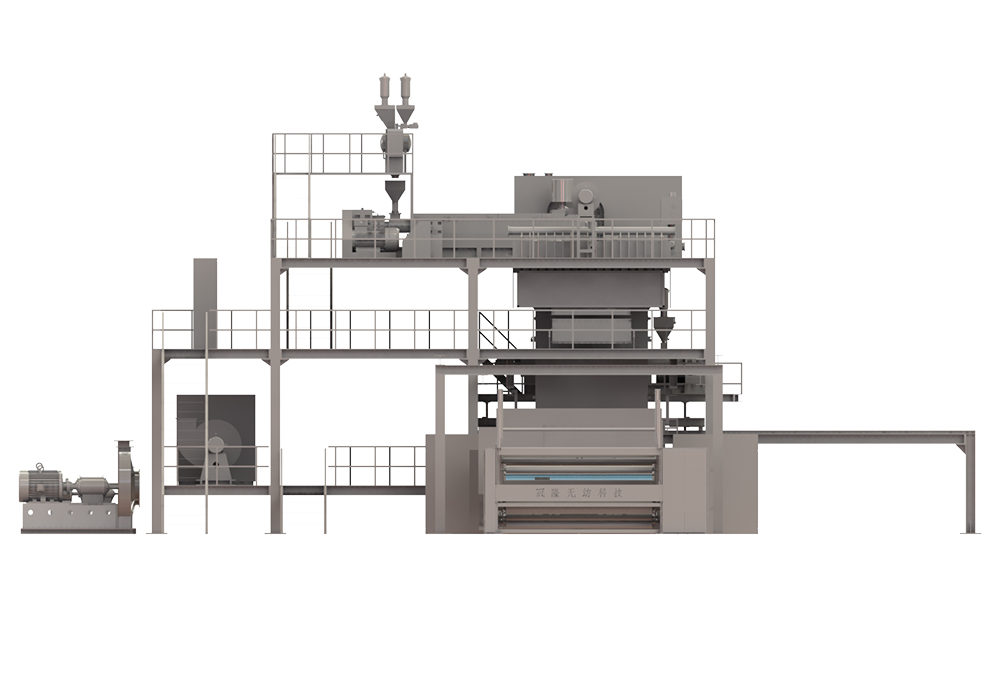

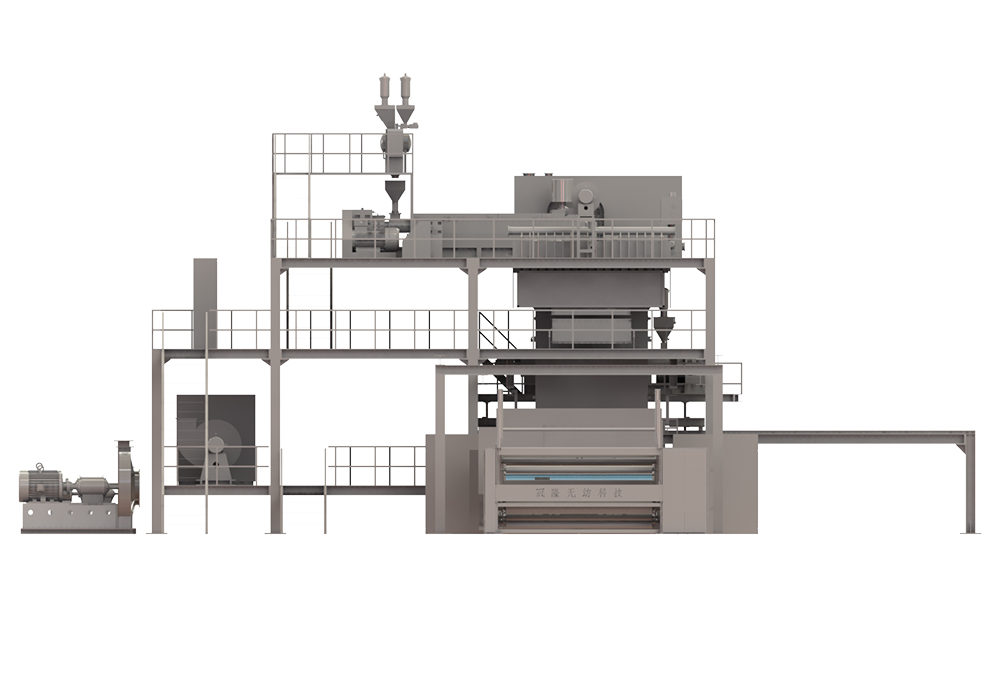

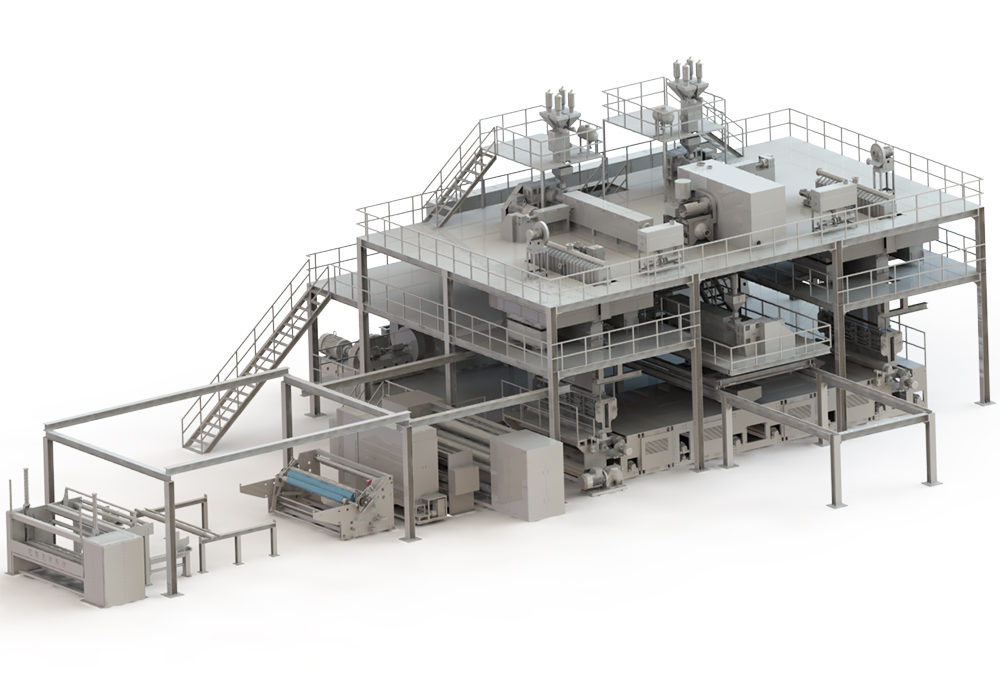

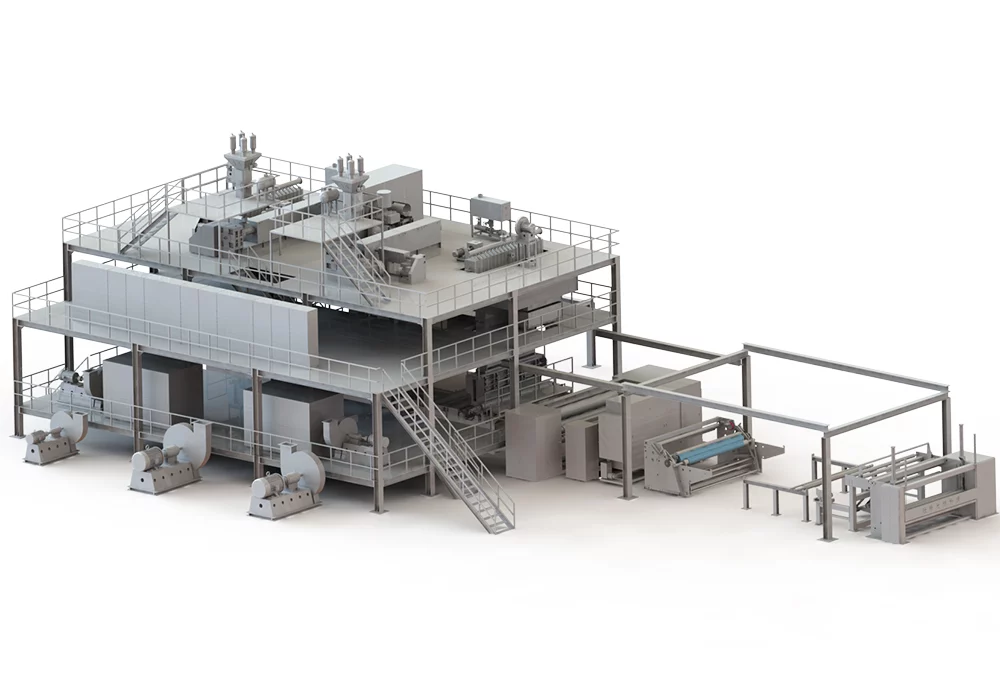

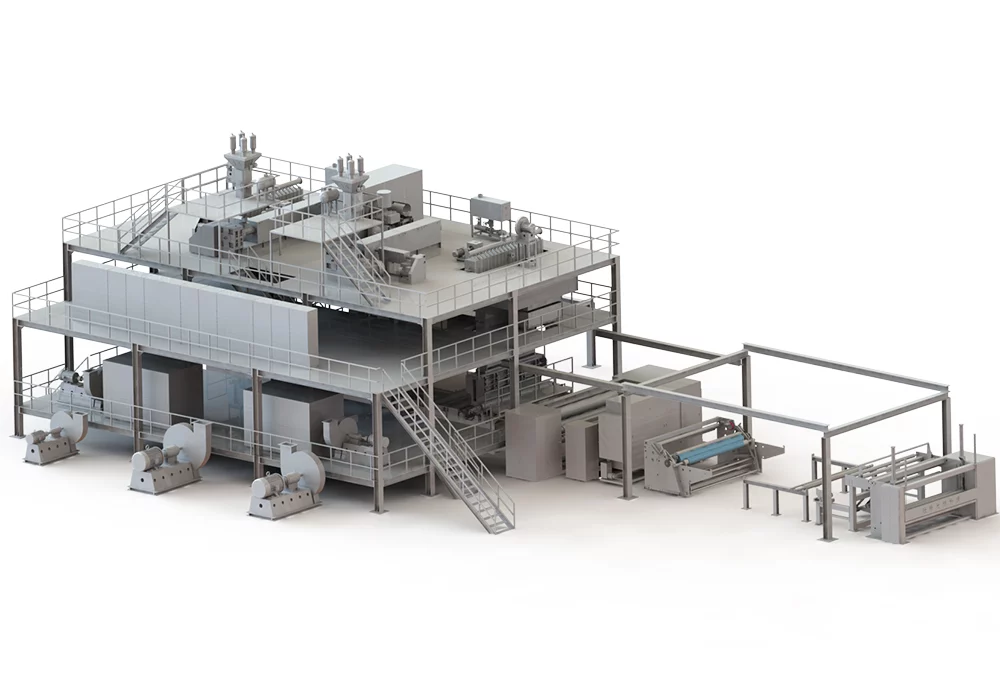

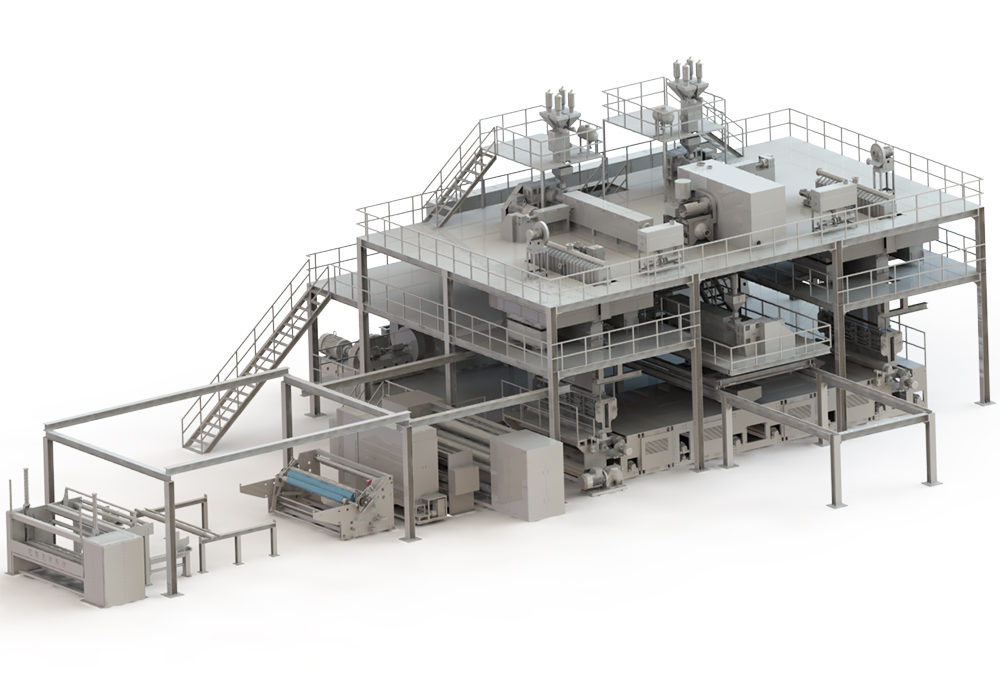

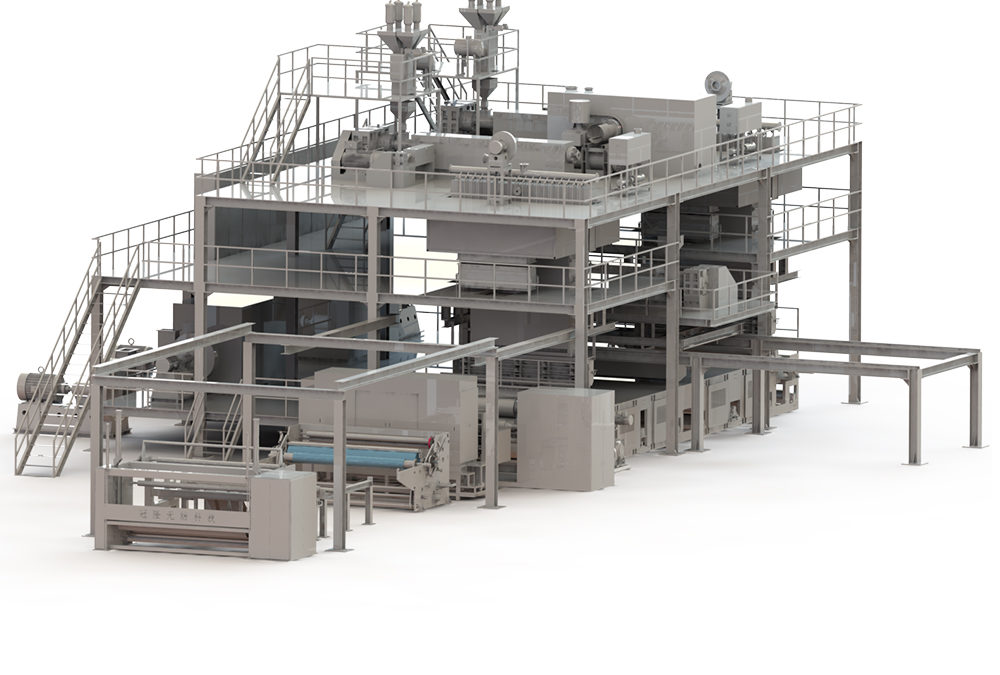

How does a spunbond nonwoven machine work? In simple terms, it transforms polymer granules into continuous filaments, lays them into a uniform web, and bonds them into a strong, functional nonwoven fabric in one continuous process. For manufacturers, this integrated...

Jan 30, 2026 | News

Choosing the right capacity for a nonwoven production line depends on your target market demand, product type, budget, space, and scalability plans. In simple terms, you should select a capacity that meets your current order volume while leaving room for growth. For...

Jan 21, 2026 | News

Choosing between an SSMMS or SMS line for medical nonwovens can be confusing, especially for new entrants to the nonwoven production industry. The answer starts with aligning product performance requirements, regulatory standards, and output expectations with the...