Why Nonwoven Machinery Is Vital for Medical Mask Production

In the medical industry, nonwoven materials form the backbone of protective masks. Nonwoven machinery for medical masks enables manufacturers to produce high-quality, consistent, and safe fabrics required for surgical masks, N95 respirators, and other medical PPE.

With the growing demand for medical masks worldwide, efficiency, reliability, and precision in production are critical. Modern nonwoven machinery ensures uniform fiber distribution, optimal filtration efficiency, and stable production rates, which are key concerns for B2B buyers in the healthcare and manufacturing sectors.

Key Features of Nonwoven Machinery for Mask Manufacturing

Industrial buyers look for machinery that combines performance, durability, and cost-effectiveness. Key features include:

- High Production Speed: Ability to produce large volumes of nonwoven fabric without compromising quality.

- Precision Fiber Control: Ensures consistent thickness and density, critical for filtration performance.

- Automated Operation: Reduces labor costs, improves safety, and increases throughput.

- Flexible Fabric Widths and Types: Supports various mask sizes and nonwoven specifications.

Investing in high-quality nonwoven fabric machine allows manufacturers to meet market demands while maintaining product standards and operational efficiency.

Choosing the Right Nonwoven Machinery

Selecting the right machinery depends on production capacity, material type, and quality standards:

- Production Capacity: Evaluate daily output needs to determine the suitable machine size and speed.

- Material Compatibility: Ensure the machinery can handle PP spunbond, meltblown, or composite materials.

- Energy Efficiency: Modern machines reduce operational costs while maintaining high output.

- Service and Support: Reliable after-sales service and maintenance support are essential for continuous production.

Maintenance and Operational Best Practices

Efficient production depends not only on the machine itself but also on proper operation and maintenance:

- Regular Cleaning and Inspection: Prevent fiber accumulation, contamination, and mechanical wear.

- Timely Replacement of Critical Components: Nozzles, rollers, and heating elements must be checked and replaced as needed.

- Operator Training: Skilled technicians reduce downtime and ensure consistent fabric quality.

- Monitoring Production Parameters: Real-time monitoring of temperature, speed, and fiber distribution helps maintain high standards.

Implementing these best practices prolongs machinery life and maximizes ROI.

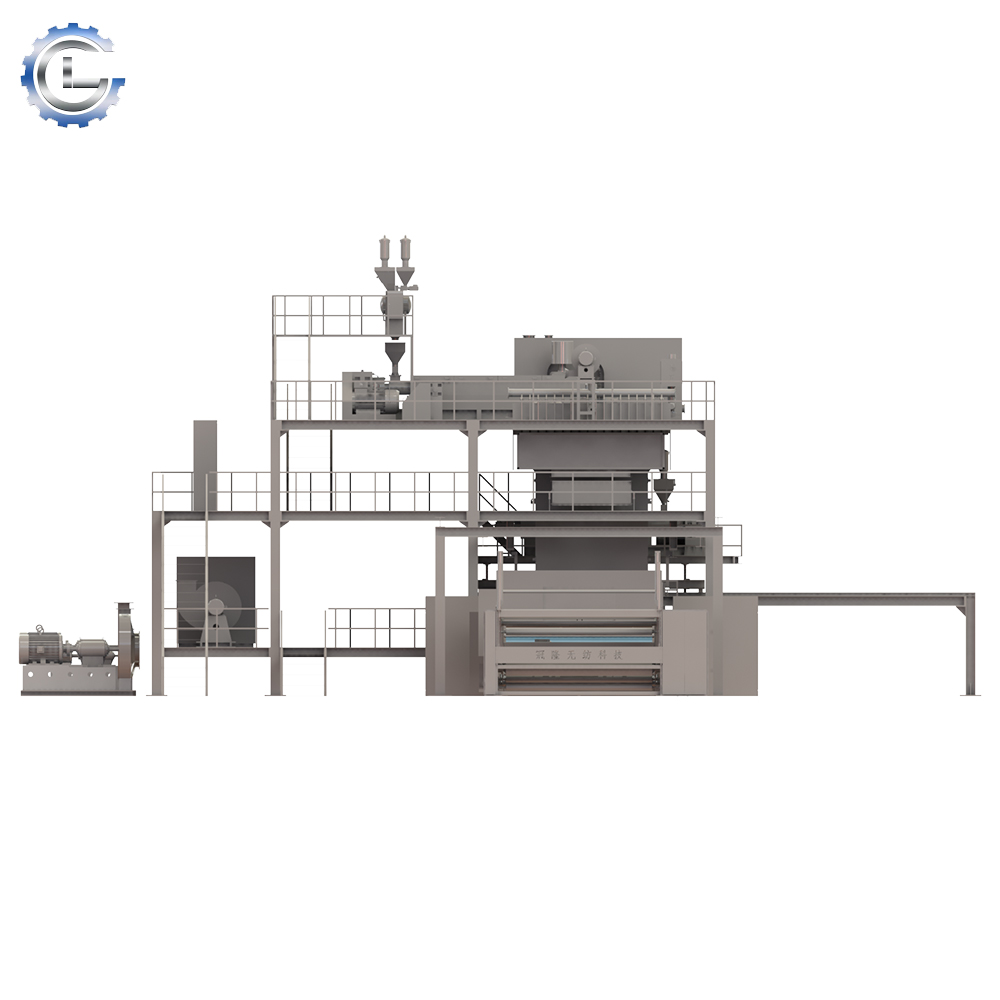

About Guanlong – Trusted Supplier of Nonwoven Machinery

Guanlong specializes in designing and manufacturing advanced nonwoven machinery for medical masks and other industrial applications. Our machines are engineered for high efficiency, durability, and precision, helping manufacturers meet increasing global demand.

Our offerings include:

- High-performance nonwoven fabric machine for PP spunbond and composite fabrics

- Expert support from leading non woven machine manufacturers

- Customized solutions to meet specific production requirements

- Long-term technical service and spare parts support

Partnering with Guanlong ensures reliable, efficient, and safe production of medical-grade nonwoven materials.