Product Description

1.Company Profile:

Guanlong has been focusing on nonwoven fabric making machine over 15 years. We combine international advanced technology and provide various holistic solutions of production lines for customers according to their request.

So far,we have manufacture hundreds of full -automatic production lines for customer from India, Indonesia, Philippines, Nepal, Russia and other countries.

2.Product details

2-1.Main data

1.1. product type

SMS Spunbond Meltblown Composite Nonwoven Fabric,SS Spunbond Nonwoven Fabric Meltblown Nonwoven Fabric

M meltblown Nonwoven Fabric

1.2. Product width:3200mm(Standard width after trimming)

1.3. Number of die heads: 2 sets of spunbond, 2 set of meltblown

1.4. Fiber fineness: spunbond system ≤1.6-2.0den, melt blown system: 2~5μ m

1.5.Fabric weight range:10-150g/ m2

1.6. Maximum production speed: 600m/min

1.7. Annual output: 4500 tons/year

2. product description

SMMS Spunmelt Nonwoven Machine is a composite line for nonwoven production which combines spunbond and meltblown manufacturing technique. It has four beams in production and can be customized for you according to your demands of production.

It adopts an intelligent electrical control cabinet and spinning drafting system. The system controlling mode features in advanced AC frequency-modulated speed, fully digital synchronized communications.

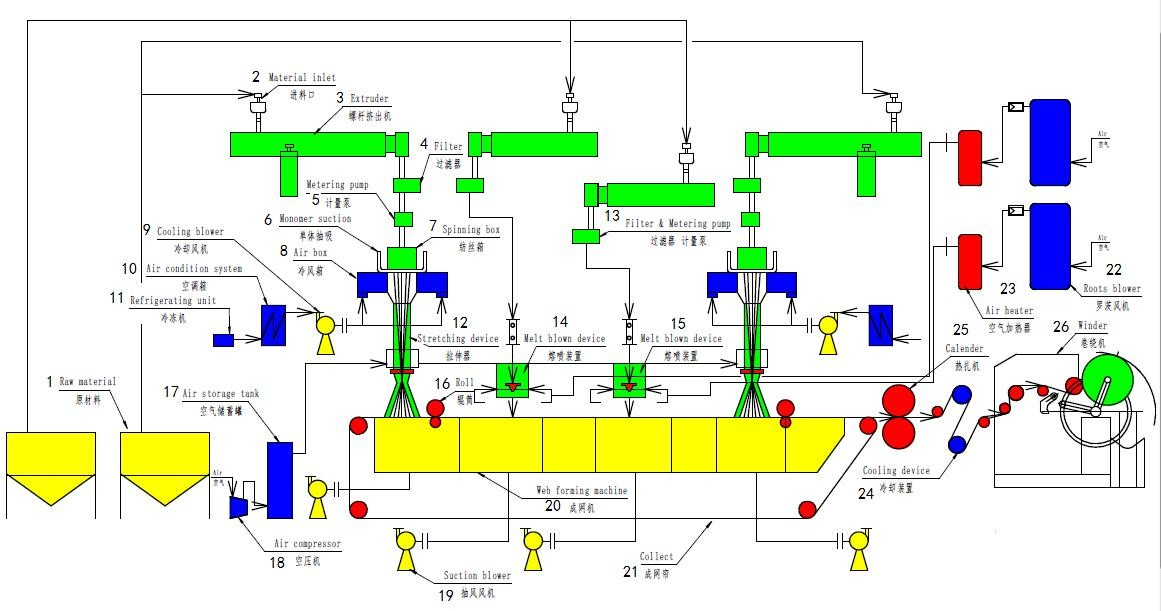

2-3.production flow

SMMS Spunmelt Nonwoven Machine is manufactured for PP composite non-woven fabrics. After the raw materials input, go through extrusion melting, filtering, metering, spinning, cooling, stretching, web spreading, thermal bonding and cutting as per requirements and then packed for storage and delivery.

2-4.the specification of smms machine

3.Main parts

3-1 Screw extruder

1. Aspect ratio L/D=30:1.

2.Screw diameter: Φ150mm

3.Siemens Bede AC motor 110kw, Fuji frequency controller

4.The spiral cylinder and screw are made of high-strength nitriding steel, equipped with resistance heater, divided into several heating zones, including a full set of electrical control devices, including power, temperature control, pressure control, etc. see the plasticizing capacity of electric control part for details

3-2 Spinning box with heating system

1)Each spinning box can distribute the melt symmetrically and equivalently

2)The melt pipeline adopts compound casing and electric heating

3)The heating power of the heat-conducting oil furnace is 48KW; the maximum heating temperature is 300 degrees, and it is heated outside the oil furnace.

3-3 Spinneret and spinning components

1)It is made of precision high temperature resistant steel, 2800 * 256 in length, The aperture is 45S /4 pairs, and the spinneret contains about 15600 holes (specific parameters are subject to the manufacturer).

2)Each set of components includes: Aluminum washer, distribution plate, aluminum clad multi-layer stainless steel filter screen

3-4 Cooling air blowing (up and down) drafting device

1)The upper drawing system adopts fully enclosed shape, and is equipped with hydraulic lifting spinneret device.

2)The inner layer of plane tempered glass, 12mm thick, adopts slit technology

3)It is divided into draft channel, diffusion channel, mobile device. The lower tension system is connected with the upper tension system. It is made of high-quality stainless steel and has an adjusting mechanism

4)Total amount of suction air: 25000m³/ h, air temperature 20-30 ℃

5)The outer surface of the upper and lower drawing devices is provided with an insulating layer

4.Our advantage

1. The whole line is well-structured and easy to operate.

2. The whole line is highly automated.

3. Control elements are of well-known made, high performance and reliable technologies.

4.The whole line are controlled by PLC and operated with touch-screen.

5.The allocation of the main frame and auxiliary equipment can be specially designed and adjusted according to customers’ requirement.

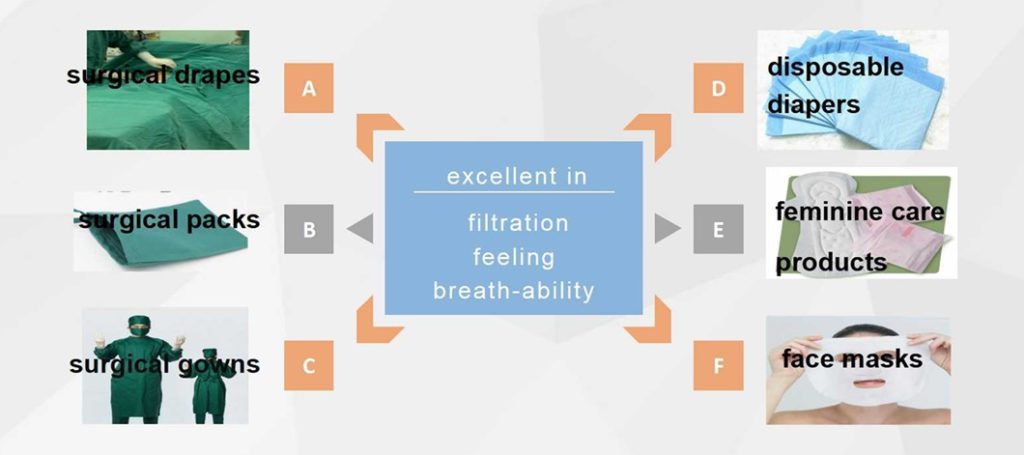

5.Application

SMMS Nonwoven fabric is featured by excellent filtration, good breath-ability, and feeling, is widely used in the hygiene & medical industry to make surgical drapes, surgical packs, surgical gowns, disposable diapers, feminine care products, face masks and so on.

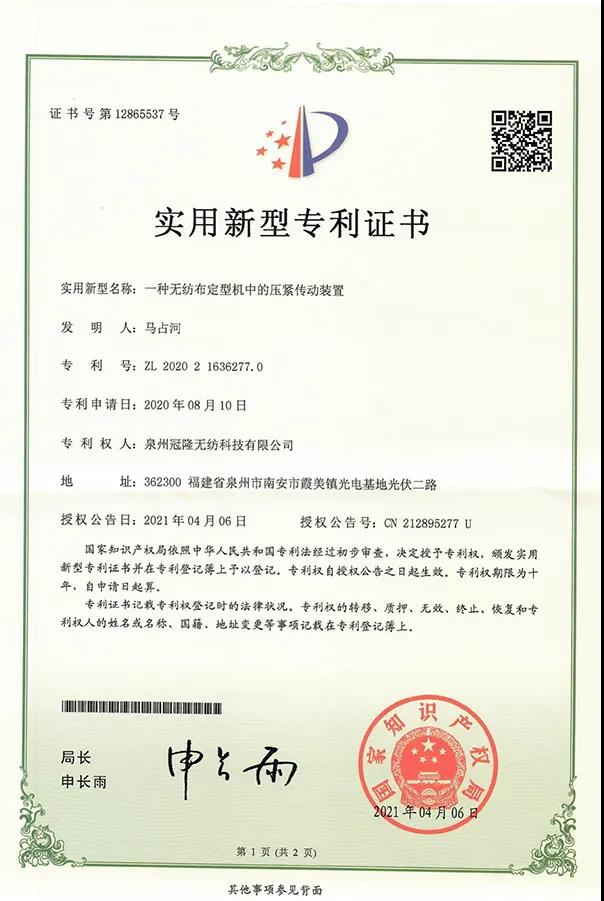

5.Certificate

6.Package and delivery