In the nonwoven textile industry, spunbond and meltblown technologies serve as the backbone of many essential products—from medical masks and filtration layers to hygiene and agriculture materials. However, the machinery used to produce these fabrics is not interchangeable. Understanding the key differences between a spunbond nonwoven fabric making machine and a melt-blown fabric machine is vital for manufacturers looking to optimize production and meet diverse market needs. At Spunlong Spuntech, a leading manufacturer of precision-engineered non-woven equipment, these differences are clearly defined and strategically developed to meet global demand.

What Are Spunbond and Meltblown Fabrics?

Both spunbond and meltblown processes fall under the larger category of nonwoven production, where fibers are bonded together without weaving or knitting. However, they serve different purposes:

- Spunbond fabrics are strong, breathable, and suitable for structural layers

- Meltblown fabrics are soft, dense, and used for fine filtration applications

Each requires specific non-woven equipment tailored to its function and fiber properties.

Core Differences Between Spunbond and Meltblown Machines

| Feature | Spunbond Nonwoven Fabric Making Machine | Melt Blown Fabric Machine |

|---|---|---|

| Fiber Diameter | 15–40 microns | 1–5 microns |

| Air Pressure Requirement | Lower | High-pressure hot air system |

| Application Focus | Hygiene backsheet, packaging, agriculture | Filtration, masks, oil absorption |

| Throughput | Higher (large volumes) | Lower (finer fiber structure, slower speed) |

| Line Configuration | Typically part of multi-layer composite systems (SMS) | Standalone or integrated in multi-layer systems |

Spunlong Spuntech offers specialized lines for both technologies, each optimized for efficiency, stability, and long-term performance.

When to Choose Which Machine?

Selecting between a spunbond nonwoven fabric making machine and a melt-blown fabric machine depends on your end product:

- Choose spunbond for products needing strength, durability, and bulk production (e.g., shopping bags, surgical gowns, crop covers).

- Choose meltblown for applications requiring fine filtration and soft-touch surfaces (e.g., N95 masks, air filters, sanitary materials).

For clients seeking both, Spunlong Spuntech provides integrated SMS or SMMS lines, combining multiple functions into a unified system.

Why Invest in Specialized Non-Woven Equipment?

Using the right machine enhances:

- Product quality: Uniform fiber distribution and bonding strength

- Production efficiency: Fewer defects, better energy use

- Market flexibility: Ability to switch or scale lines for different applications

- Regulatory compliance: Especially important in medical-grade production

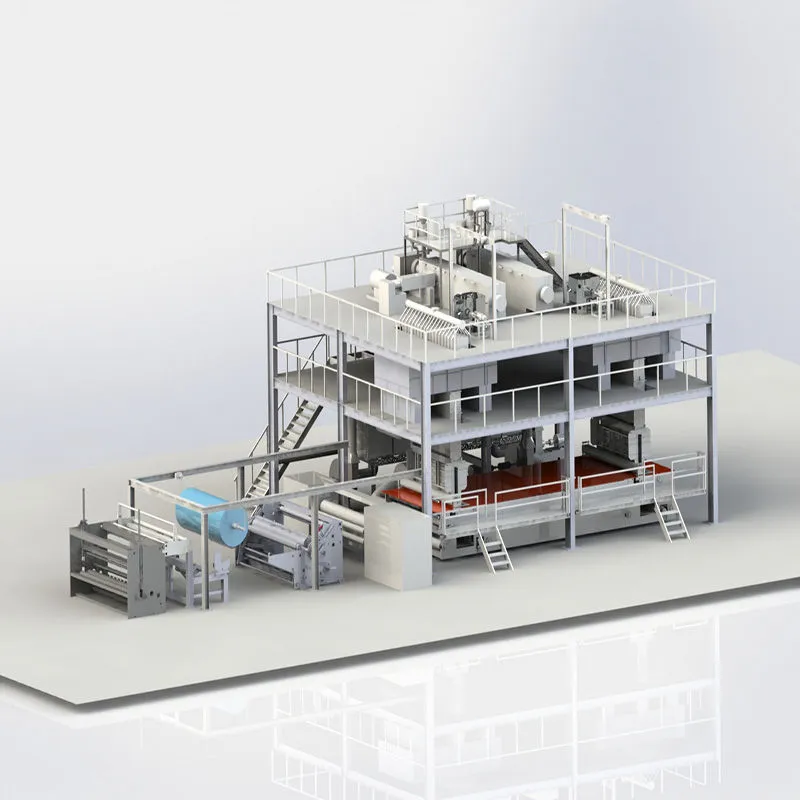

Spunlong Spuntech’s full suite of non-woven equipment ensures seamless operation across all stages—from polymer feeding and extrusion to web forming and winding.

Spunlong Spuntech: One Supplier, Multiple Technologies

As a trusted industry partner, Spunlong Spuntech delivers more than machines—it delivers complete nonwoven solutions. Whether you need a high-output spunbond nonwoven fabric making machine or a precision-controlled melt-blown fabric machine, Spunlong offers:

- Modular line design for custom factory layouts

- PLC & HMI automated control systems

- Fast installation and after-sales support

- Global experience across hygiene, filtration, and packaging industries

With a growing client base across Asia, Europe, and the Americas, Spunlong continues to set the benchmark for quality and reliability in nonwoven manufacturing.

Make the Right Investment in Nonwoven Production

The difference between spunbond and meltblown machines isn’t just technical—it’s strategic. Choose the right solution for your product goals with the expertise of Spunlong Spuntech. Contact us today to explore our full range of advanced non-woven equipment and tailored production lines.