Product Description

1.Company Profile:

2.Product details

2-1:Main Technology data

1.Fabric width:2400mm(Availed width)

2.Maximum winding diameter:Φ1500MM

3.Capacity:According70 g/㎡,9-10t/24h

4.Monofilament size:<2.5d

5.Fabric weight:10~200 g/㎡

6.Designed speed:150M/MIN ;(Working speed:130 M/MIN)

7.Equipment size:length 15 *width10* height 11

2-2. product description

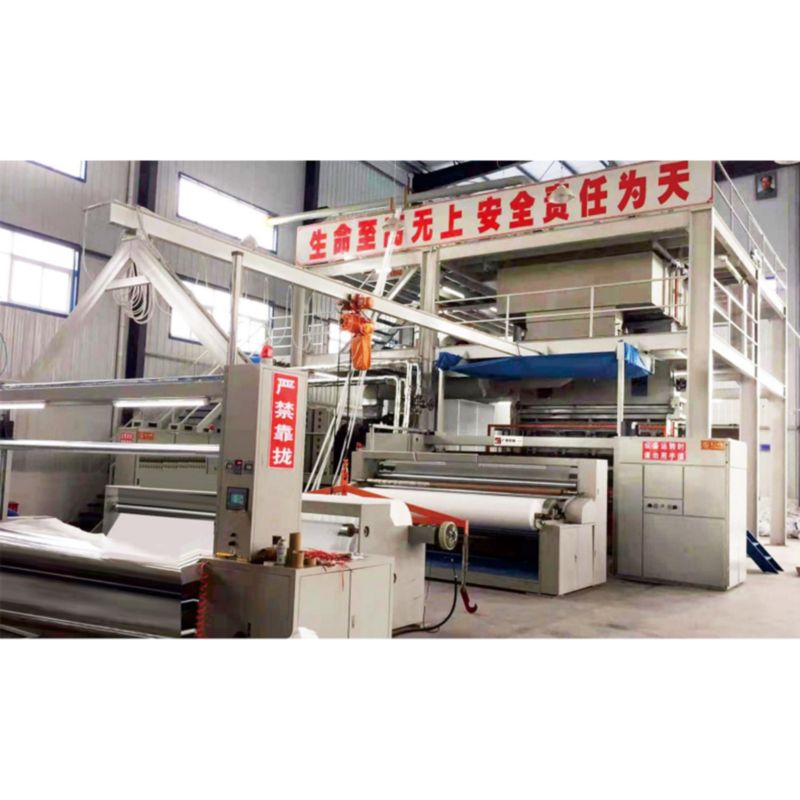

S Spunbond Nonwoven Machine adopts an intelligent electrical control cabinet and spinning drafting system. The system controlling mode features in advanced AC frequency-modulated speed, fully digital synchronized communications.

S Spunbond Nonwoven Machine is featured by lower investment, compact construction, small covering area, and labor-saving.

S Spunbond Nonwoven Machine is a single-beam professional manufacturer of single-layer nonwoven fabric equipment which is manufactured for PP/PET/PLA/Bi-Component Spunbond nonwoven fabrics’ production. After the raw materials input, undergo the process of extrusion, spinning, quenching, closure air stretching, web formation, calendaring, winding and cutting as per requirements and then packed for storage and delivery.

2-3 Technical Parameter

2-4 Production line work flow

1.This production line use “slit negative pressure draft” technology

2.Process flow: PP raw material Feeding→Extrusion Melting → Filtering → Metering →spinning→Cooling→Stretching →Web spreading→Thermal bonding →slitting→collecting

3.Main parts

1.Maximum working pressure: 16MPa

2.Maximum working temperature: 310℃

3.Single cylinder filter area: 0.5-19㎡

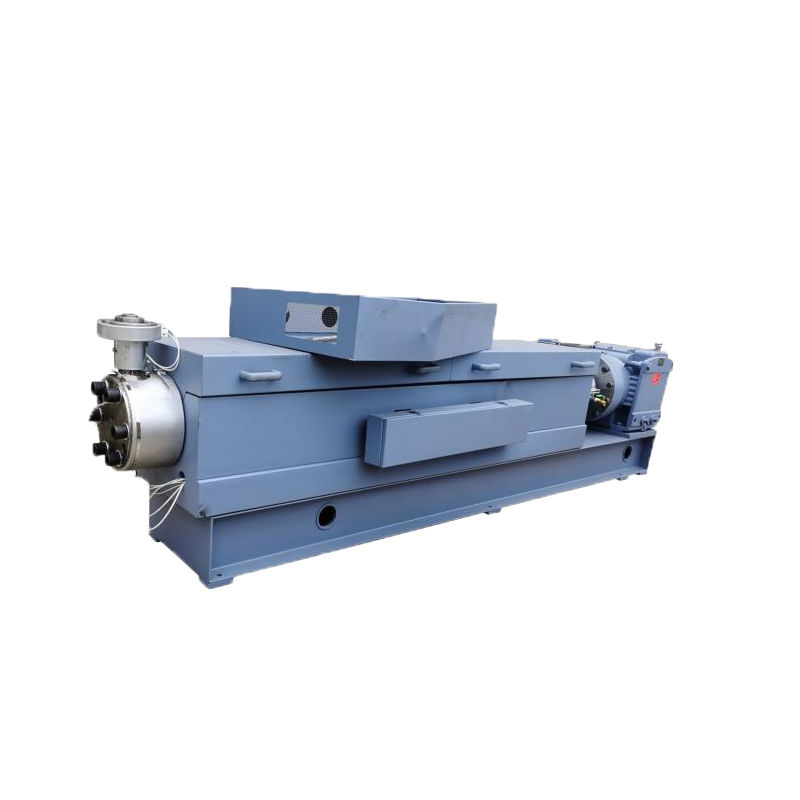

1. Aspect ratio L/D=30:1.

2.Screw diameter: Φ150mm

3.Siemens Bede AC motor 110kw, Fuji frequency controller

4.The spiral cylinder and screw are made of high-strength nitriding steel, equipped with resistance heater, divided into several heating zones, including a full set of electrical control devices, including power, temperature control, pressure control, etc. see the plasticizing capacity of electric control part for details

1.The main driving roller is made of seamless steel tube

2.Cutting speed:800-1000m/min

3. Siemens Bede AC motor, 15kw * 1 set, Fuji variable frequency controller of Japan

4.Minimum cutting width: 100 mm

5.Maximum winding diameter: 1000mm

6.Number of slitting knives 16 sets

7. 3 carbon fiber gas expansion shafts

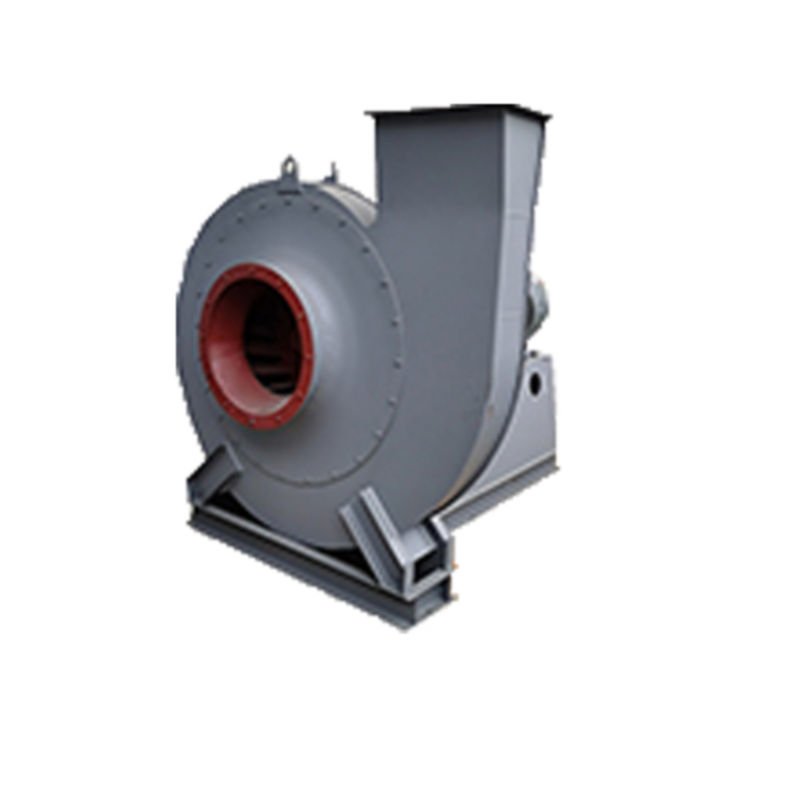

1.The speed of exhaust fan is adjustable2.Accessories: GD-SM-SO2 static mixer

3.Total air volume: 15000-23000 m³/ h

4.Air pressure regulator: Fuji Inverter(RKC-F900)

5.The fan power is 75KW * 1 set, 90kW * 1 set, including the exhaust pipe,and the suction air is discharged to the outdoor

6. The power of cold air fan is 75kw, 2sets, Siemens Bede motor is adopted

1.Power:45KW AC Motor

2.Heating: Oil Heating

4.Application

Disposable face mask, surgical cap,surgical mask,disposable garments,surgical gown, etc

Baby and adult diapers: Top sheets, back sheets, ears, tapes, landing zone;

Female hygiene: sanitary pad,Top sheets, wings;

Cleaning wipes: Baby care, cosmetics, etc.

The non woven fabric can use for geotextile , use for banana cover, etc

The non woven fabric can use of different type of non woven bag making,such as non woven handle bag, non woven t-shirt bag,non woven box bag, etc

The non woven fabric can use of wardrobe ,non woven closet, non woven suit cover,lining cloth,bed cover etc

The non woven fabric widely use for automobile filter , water filtration,air filtration,etc

5.Packing & Shipping