PP S Spunbond Machine

A PP (polypropylene) spunbond machine is a type of equipment used in the manufacturing of non-woven fabrics made from polypropylene fibers. These fabrics are commonly used in a wide range of applications, including hygiene products, medical products, geotextiles, and automotive components.

The process of making non-woven fabrics using a PP spunbond machine involves extruding molten polypropylene through spinnerets to create continuous filaments. These filaments are then laid down onto a conveyor belt and bonded together to form a non-woven fabric. The bonding process can be achieved through various methods, such as thermal bonding or chemical bonding.

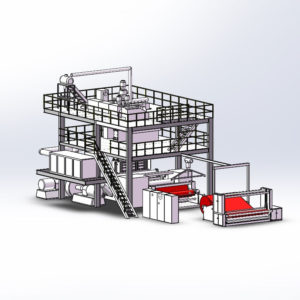

PP spunbond machines can vary in size and configuration, depending on the specific needs of the manufacturer. They typically include an extruder, spinneret, quenching system, conveyor belt, bonding equipment, and winding equipment. The output capacity of a PP spunbond machine can range from a few hundred kilograms to several thousand kilograms per day.

Overall, PP spunbond machines are an essential tool for the production of high-quality non-woven fabrics made from polypropylene fibers.

Showing all 7 results

-

100% PP S Spunbond Nonwoven Fabric Making Machine Production Line for PP Nonwoven Fabric(10-250GSM)

-

CE Certificate Single Beams S PP Spun Bond Non Woven Fabric Making Production Line

-

High Quality Single S Nonwoven Machinery For Non Woven Fabric

-

Fully Automatic High Quality PP Spunbond S Non Woven Fabric Machine Fabric Making Machine

-

2400mm Spunbond Nonwoven S Fabric Production Line

-

S 1.6m Nonwoven Fabric Making Machine

-

PP S Spunbond Nonwoven Fabric Making Machine